Capacity Visibility: How We Guarantee Zero Shortages and Zero Downtime for White-Label Server Brands

Building Supply Chain Confidence Through Transparent Production Capacity, Material Management, and Smart Planning Systems

For white-label server brands, hardware availability is the lifeline of the business. A single delayed shipment—or worse, a production halt—can cascade into missed delivery commitments, partner dissatisfaction, and lost market share.

This is why modern OEM and SI customers demand not only competitive pricing, but guaranteed, uninterrupted supply.

At Shenzhen Angxun Technology Co., Ltd., we provide exactly that.

Through capacity visibility, material transparency, and predictive planning, we ensure that customers never face stockouts, production delays, or deployment interruptions.

1. Why White-Label Customers Need Capacity Visibility

White-label hardware buyers often face three common risks:

Unpredictable output during peak seasons

Material shortages caused by upstream supply fluctuations

Sudden production gaps when vendors lack planning capabilities

These risks directly affect brand reputation—especially for companies selling under their own label.

To solve this, Angxun built a fully transparent and data-driven supply chain system that gives customers confidence long before production begins.

2. Our Capacity Reserve: Always Ready, Always Scalable

With over 20 years of manufacturing experience and fully integrated SMT + DIP + assembly lines, Angxun maintains a robust capacity structure:

✔ Multiple SMT Lines With Flexible Configuration

Allows rapid switching between Intel, AMD, AIO, and industrial motherboard models.

✔ Dedicated Production Slots for Key Customers

Ensures stable weekly output even during peak seasons.

✔ On-Demand Capacity Expansion

Our modular production model allows quick scaling to meet urgent or large-volume orders.

✔ Dual-Shift + Weekend Overflow Mechanism

Guarantees uninterrupted delivery schedules during critical project periods.

With transparent dashboards and predictable throughput, customers can forecast availability with confidence.

3. Material Management: From Uncertainty to Full Transparency

The core of capacity visibility is material visibility.

Angxun’s material management system provides:

✔ Real-Time Component Tracking

We track every key component—chipsets, power modules, ICs, memory sockets—through ERP integration.

✔ Safety Stock Mechanisms for Long-Lead Materials

Critical components like chipsets and power controllers have designated buffer levels to eliminate shortage risks.

✔ Multi-Supplier Strategy

Reduces dependence on a single source and protects customers during global supply fluctuations.

✔ Advanced FIFO + Lot Traceability

Ensures batch consistency and fast root-cause tracing when needed.

This disciplined approach ensures that production never stops due to missing materials.

4. Smart Production Planning: Predictive, Not Reactive

Unlike traditional factories that rely on manual scheduling, Angxun operates a modern planning architecture:

✔ APS (Advanced Planning & Scheduling)

Automatically forecasts capacity, material consumption, and expected delivery cycles.

✔ Customer Forecast Integration

For long-term clients, we link production plans directly with monthly and quarterly demand forecasts.

✔ Real-Time Production Monitoring

Every stage—from SMT to assembly to QA—is monitored through digital dashboards.

✔ Automatic Risk Alerts

If any material, process, or cycle time deviates from plan, the system triggers early warnings to ensure corrective action.

This gives customers a predictable and stable supply chain, not a reactive one.

5. Zero Shortages, Zero Downtime: Our Supply Chain Commitment

By combining capacity reserve, material visibility, and predictive planning, Angxun ensures:

No forced shipment delays

No unplanned production shutdowns

No hidden bottlenecks

No surprise shortages

No last-minute firefighting

This stability is especially critical for:

White-label brands with strict SLA commitments

System integrators requiring consistent delivery

Overseas clients managing long logistics cycles

Cloud providers scaling deployments on tight timelines

When customers scale, we scale with them—without disruption.

6. Why Customers Trust Angxun as Their Long-Term Manufacturing Partner

For many OEM and white-label brands, Angxun is not just a supplier but a supply chain insurance policy.

Our advantages include:

• 20+ years of R&D + manufacturing experience

• Integrated production across SMT, DIP, assembly, and burn-in

• Transparent supply chain dashboards and traceable data

• Dedicated capacity for key overseas customers

• Rigorous QA processes ensuring batch consistency

• Long-term supply commitment for mainstream Intel / AMD platforms

With this foundation, customers know they can build their product roadmap on top of Angxun—confidently.

Conclusion: Capacity Visibility Is the New Competitive Advantage

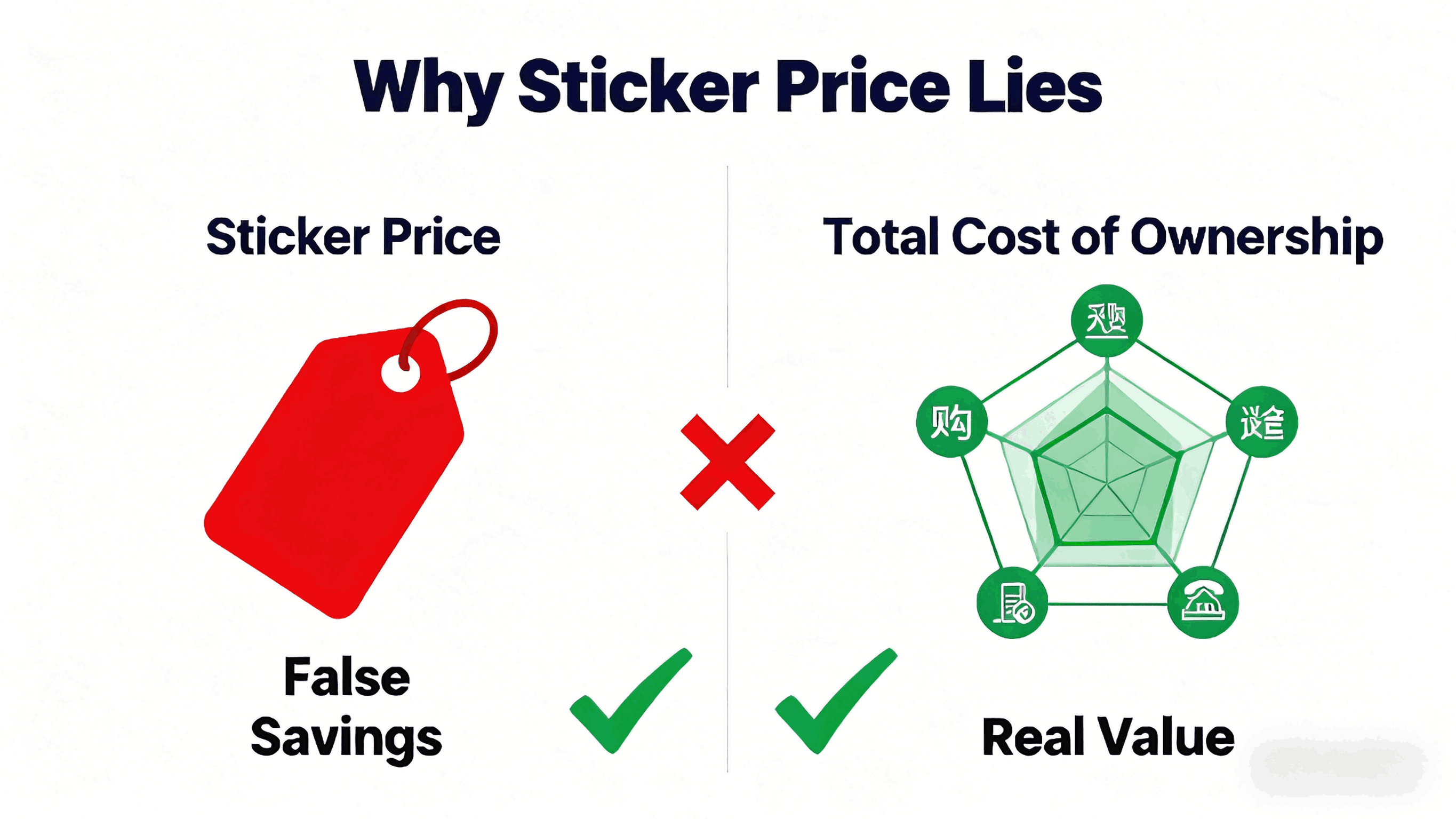

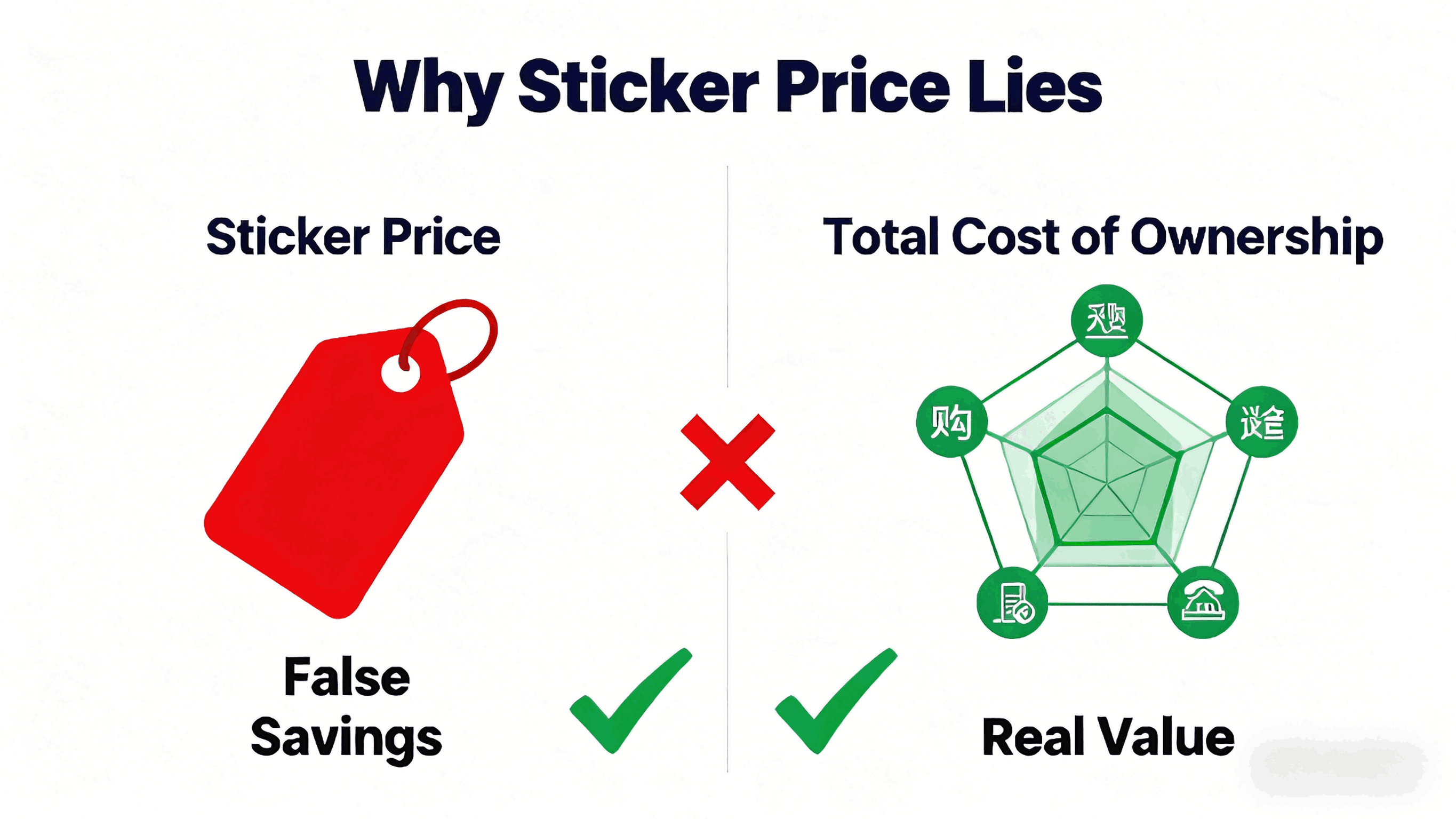

In the white-label server industry, the winners are not defined by low prices alone—but by supply chain reliability.

Shenzhen Angxun Technology ensures uninterrupted supply through:

Visible capacity

Transparent materials

Predictive planning

Consistent execution

This is how we help customers deliver on promises, protect their brand reputation, and scale faster in global markets.