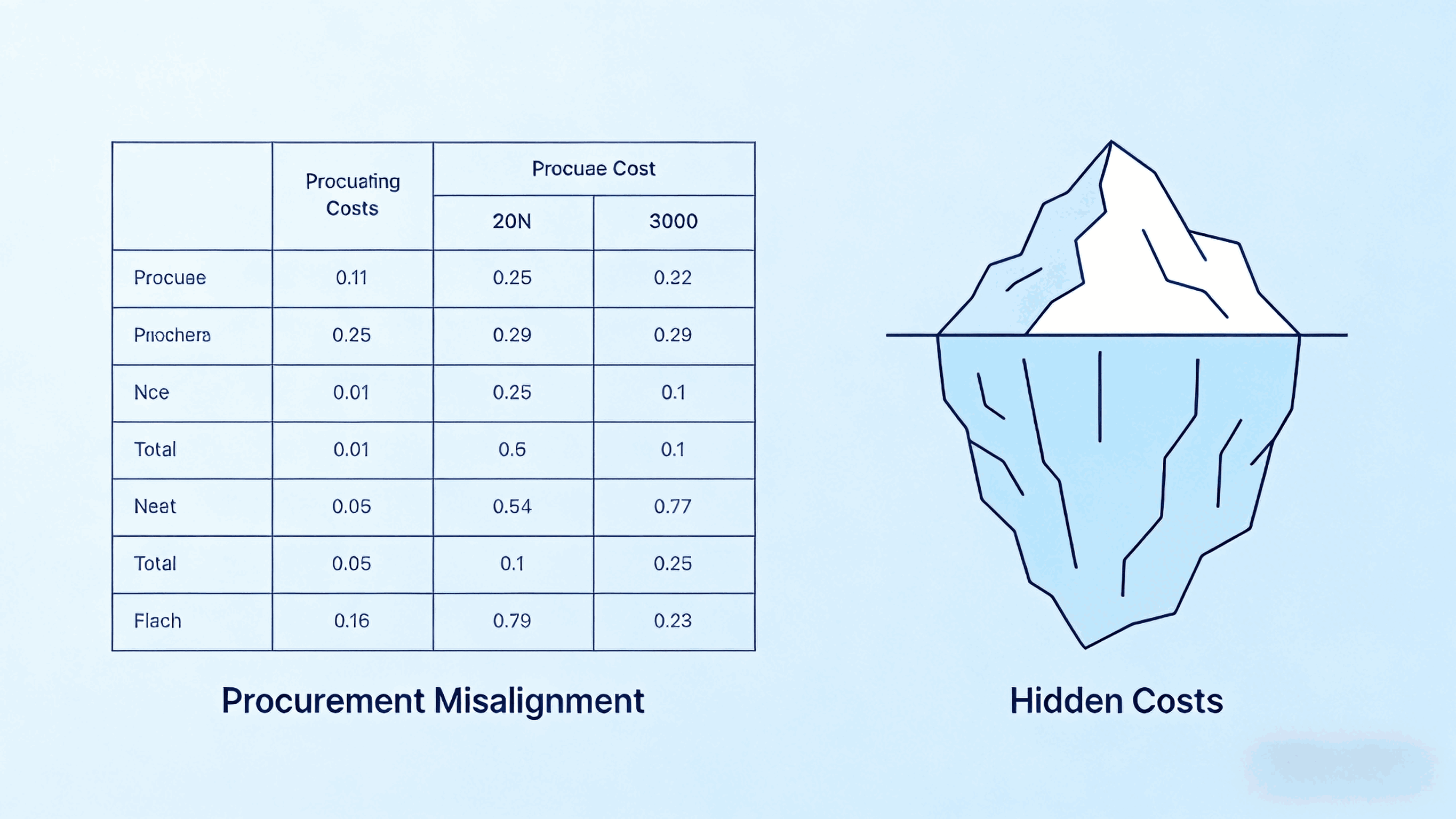

A Procurement and OEM Perspective on Risk, Stability, and Scale commodity Same capacity. Same speed. Same JEDEC standard. Lower price wins. unvalidated memory is one of the most expensive components you can buy 1. “JEDEC-Compliant” Does Not Mean “Production-Ready” Most memory modules on the market are technically compliant with JEDEC standards. They may even appear on a motherboard’s compatibility list. However, JEDEC compliance only guarantees: Electrical and timing standards at nominal conditions Basic interoperability in reference configurations not Stable memory training across BIOS versions Predictable behavior under AVX or virtualization workloads Consistency across manufacturing batches Reliability at elevated temperatures or dense chassis For production environments, these gaps matter. 2. The Most Common Failure Modes of Unvalidated Memory From OEM and cloud provider field data, memory-related issues rarely appear as total failures. intermittent, hard-to-diagnose problems Typical symptoms include: Cold-boot failures or extended training times Random kernel panics under load ECC correctable error storms Performance degradation due to retraining Nodes that behave differently despite identical BOMs These failures consume engineering time far beyond their apparent severity. 3. Why Procurement Often Underestimates Memory Risk From a procurement perspective: Memory SKUs look interchangeable Vendor datasheets appear identical Cost savings are immediate and measurable From an engineering perspective: Memory behavior varies by die vendor, rank, and density Mixed lots behave differently under thermal stress BIOS updates can expose marginal timing issues misalignment between short-term savings and long-term cost 4. The Real Cost Model: What Unvalidated Memory Actually Costs Based on OEM and system integrator experience, a single memory-related issue can trigger: Multiple support tickets Engineering hours spent reproducing non-deterministic failures BIOS rollbacks or custom firmware workarounds On-site diagnostics or node replacements RMAs that cannot be conclusively justified In many cases: One memory-related field escalation costs more than the price difference of validated DIMMs for an entire rack. 5. Scale Amplifies Small Memory Issues In small deployments, marginal memory behavior may go unnoticed. At scale: 1% instability becomes dozens of failing nodes Training variance breaks automation Predictability disappears For cloud providers, this directly impacts: Fleet-wide consistency SRE efficiency SLA compliance For OEMs, it leads to: Higher RMA rates Reputation damage Reduced customer trust 6. What “Validated Memory” Really Means Validated memory is not just “on the list.” It has been tested for: Vendor ID and die consistency Rank and density behavior Mixed-DIMM population scenarios ECC behavior under sustained stress Cold-boot and retraining reliability Performance stability across BIOS revisions Thermal behavior in dense systems predictably across time, workload, and batch 7. Why High-Maturity Teams Treat Memory as a Stability Component Experienced OEMs and cloud infrastructure teams: Lock memory SKUs early Track memory behavior across firmware lifecycles Avoid opportunistic substitutions Validate memory as part of a complete system They understand: control variable Conclusion Unvalidated memory rarely fails loudly. It fails quietly, repeatedly, and expensively. For procurement teams and OEMs building white-box servers, the question is not: “Is this memory compatible?” The real question is: “Will this memory behave the same way in every system, every time?” predictability is the real cost savings

Contact: Tom

Phone: 86 18933248858

E-mail: tom@angxunmb.com

Whatsapp:86 18933248858

Add: Floor 301 401 501, Building 3, Huaguan Industrial Park,No.63, Zhangqi Road, Guixiang Community, Guanlan Street,Longhua District,Shenzhen,Guangdong,China

We chat