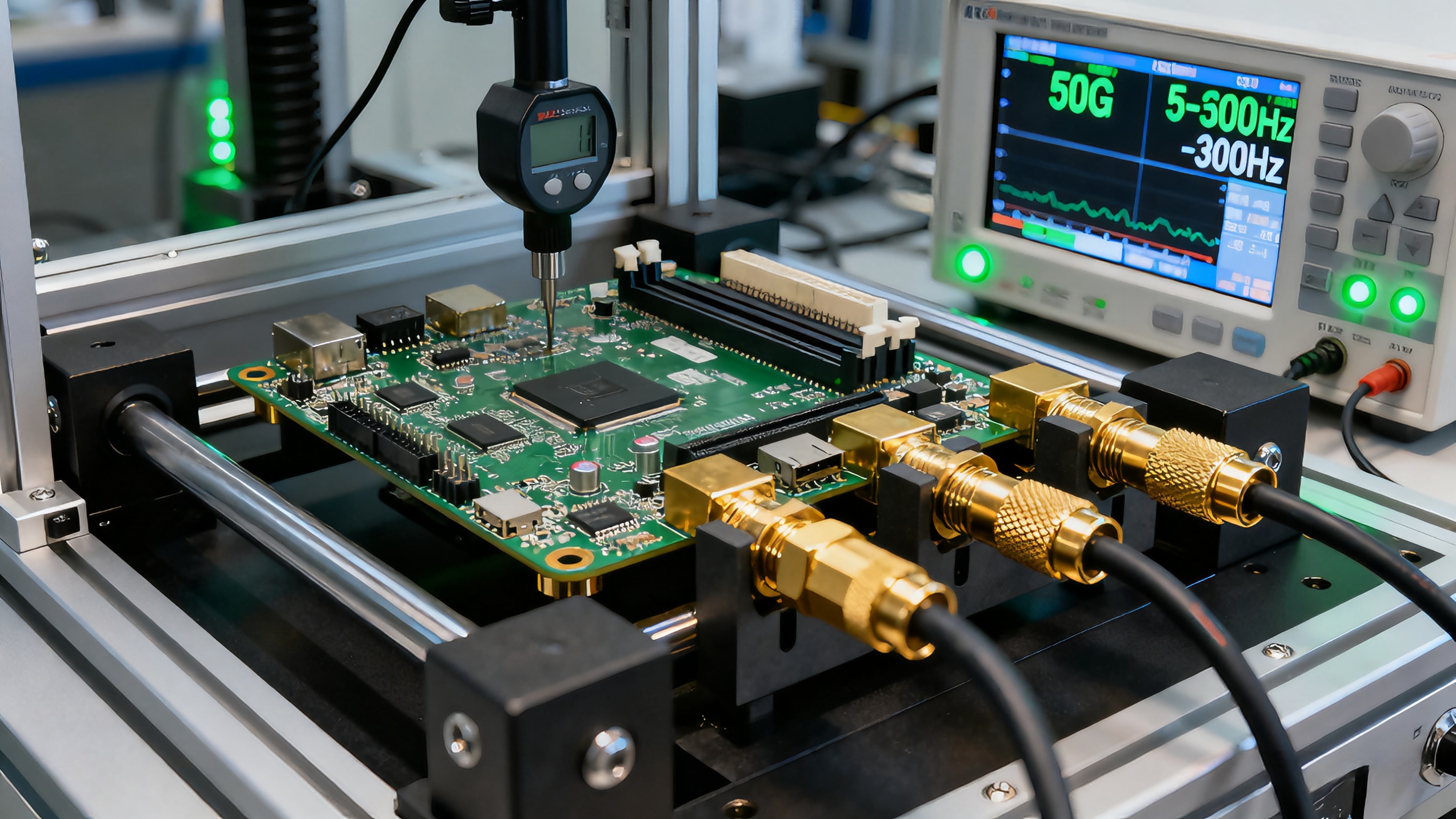

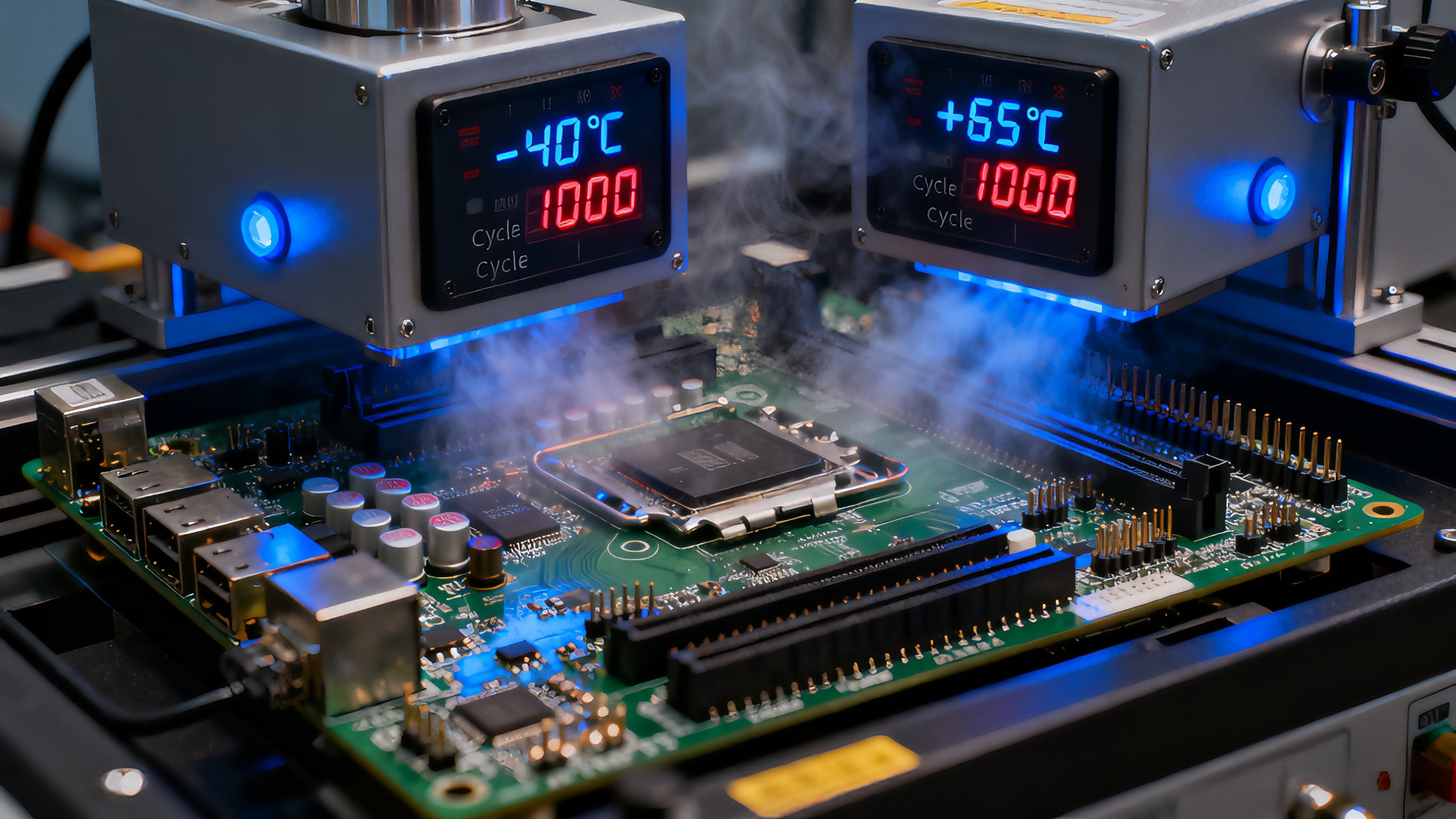

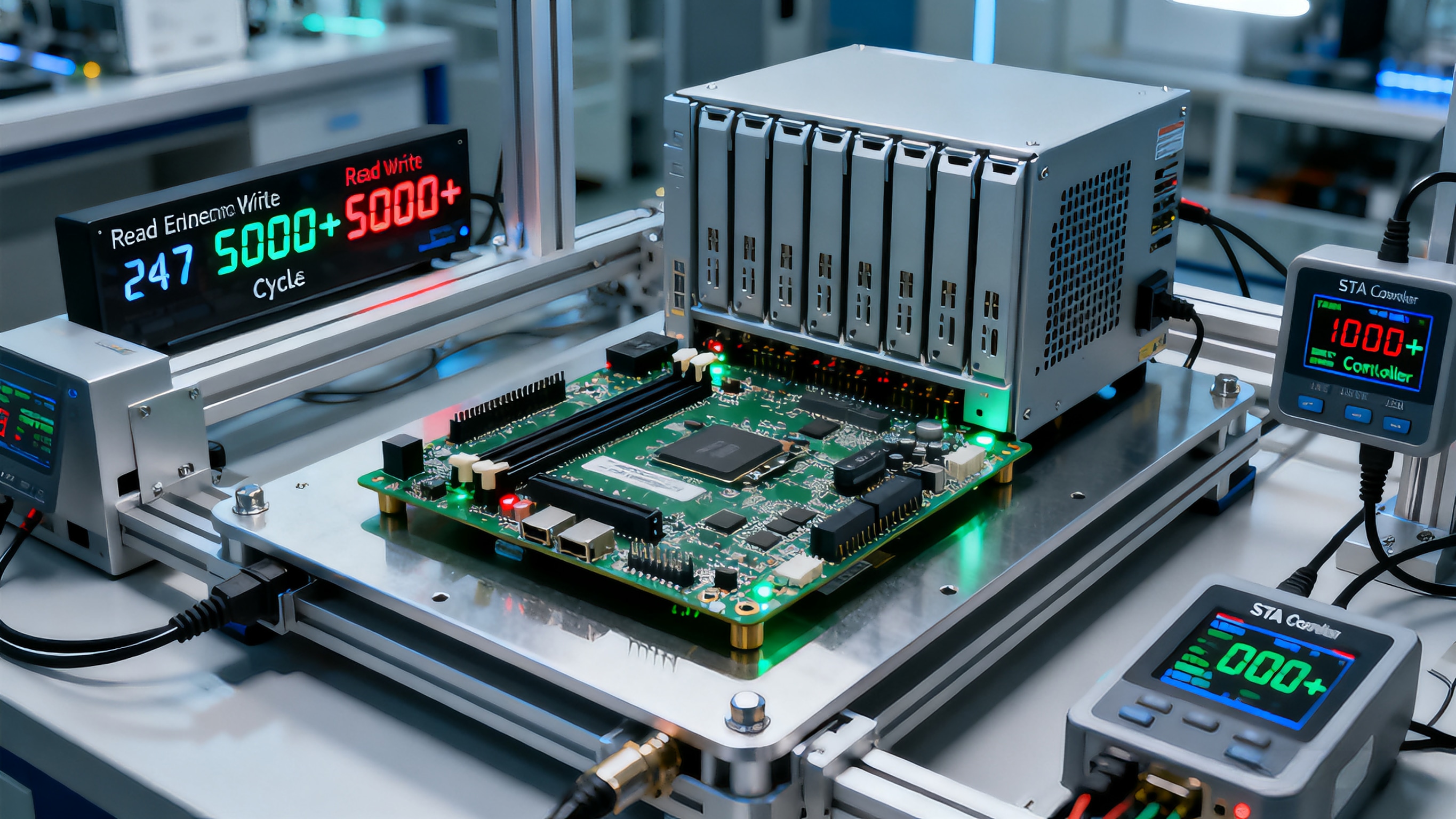

The brutal testing protocols that separate consumer-grade hardware from industrial-grade solutions. When your manufacturing facility in Shenzhen loses $15,000 per hour of downtime, or your edge computing nodes operate in desert heat, "probably reliable" isn't good enough. As an ODM/OEM motherboard manufacturer, we've developed testing protocols that predict failure before it happens in the field. Why Standard Testing Isn't Enough Most consumer motherboard testing follows basic protocols: 48-hour burn-in at room temperature Basic functionality checks Maybe some gaming benchmarks The problem? This catches immediate manufacturing defects but tells you nothing about whether the board will survive: 3 years of 24/7 operation in a NAS enclosure Thermal cycling from -20°C to 60°C in industrial environments 10,000+ power cycles in digital signage applications Vibration-induced solder joint fatigue in transportation systems Our Accelerated Life Testing (ALT) Arsenal Thermal Shock Testing: From Arctic to Desert in Minutes The Process: Boards move between extreme chambers: -40°C to +85°C transitions in under 30 seconds 1,000+ cycles (simulating 5+ years of daily temperature variation) Monitoring for solder joint cracks, PCB delamination, component failure What We Learn: Consumer boards typically fail between cycles 200-400. Industrial boards like our AMD Ryzen Embedded series are specified to survive 1,000+ cycles. The difference comes from: Industrial-grade capacitors with wider temperature tolerance Thicker PCB copper layers (2oz vs. standard 1oz) Underfill application on BGA components High-Load Power Cycling: Simulating Years of Server Stress The Setup: Simultaneous CPU, memory, and PCIe load cycling Rapid power on/off cycles (every 30 seconds for 72 hours) Monitoring voltage regulation stability and component temperatures Real Finding from Recent Testing: We discovered that a particular VRM MOSFET, while adequate for gaming workloads, would fail within 6 months of 24/7 database operation. The fix? Switching to a parallel MOSFET configuration with better thermal characteristics—adding $1.20 to our BOM cost but extending lifespan from 2 years to 7+ years. Connector Durability: The 10,000-Insertion Test The Reality Check: While most users insert RAM and expansion cards a handful of times, industrial and server environments see far more frequent changes: PCIe slots: Tested to 5,000 insertion cycles (vs. consumer standard of 500) SATA ports: 10,000 insertion target DIMM slots: 2,500 cycle minimum Manufacturing Insight: We achieved this not through exotic materials but via: Thicker gold plating (30μ" vs. consumer 5-10μ") Reinforced retention mechanisms Optimized insertion force distribution Case Study: NAS Motherboard Failure Prediction The Scenario: A client needed motherboards for 24/7 NAS operation with 5-year warranty requirements. Our Testing Protocol: Thermal Aging: 1,000 hours at 85°C with continuous read/write operations Vibration Testing: 50G shock testing and 5-500Hz vibration sweeps Power Interruption: 5,000+ rapid power cycle tests The Failure We Caught: After 3,200 power cycles, we detected SATA controller communication errors. Root cause analysis traced it to a capacitor discharging too slowly during quick reboots. The fix—a minor circuit modification—prevented field failures that would have started appearing around year 2. The Cost of Skipping Deep Testing Financial Impact Examples: $250,000: Recall and replacement cost for a batch of 5,000 industrial panels (avoided by catching a touch controller issue during thermal testing) $85,000: Field service cost for a mining operation using consumer boards in industrial environments (predicted by our vibration testing) Unknown brand damage: From a major European retailer whose digital signage failed during holiday season (simulated by our continuous operation testing) What This Means for Your Business For System Integrators: Look for manufacturers who can provide ALT data, not just basic specifications Demand failure rate predictions based on actual testing, not theoretical MTBF calculations Ask about the specific testing protocols used for your application environment For OEM/ODM Partners: Our testing reveals that most field failures are predictable through proper accelerated testing: 73% of failures relate to thermal cycling damage 18% stem from mechanical wear (connectors, sockets) 9% come from electrochemical migration or component aging Beyond the Hype: Real Industrial vs. "Industrial-Labeled" Many consumer motherboard manufacturers simply add thicker heatsinks and call it "industrial." True industrial qualification requires: Material Differences: High-Tg PCB materials (170°C+ glass transition temperature) Industrial-grade solid capacitors (5,000-10,000 hour rated vs. 2,000-5,000 for consumer) Conformal coating for humidity and contamination protection Design Philosophy: Conservative component derating (operating at 50-70% of rated maximums) Redundant power circuits Comprehensive circuit protection The Testing Transparency You Deserve When evaluating motherboard suppliers, ask these critical questions: "What's your thermal cycling test protocol and passing criteria?" "Can you show me vibration testing results for my application environment?" "What's your demonstrated MTBF, and how was it calculated?" "What specific failures has your testing prevented in recent production?" The answers will quickly separate true industrial manufacturers from marketing claims. We're an ODM/OEM motherboard manufacturer specializing in AMD-based solutions across desktop, industrial, server, and embedded applications. Our accelerated life testing protocols ensure your systems survive long after the warranty expires. Contact us to discuss your specific reliability requirements.

Contact: Tom

Phone: 86 18933248858

E-mail: tom@angxunmb.com

Whatsapp:86 18933248858

Add: Floor 301 401 501, Building 3, Huaguan Industrial Park,No.63, Zhangqi Road, Guixiang Community, Guanlan Street,Longhua District,Shenzhen,Guangdong,China

We chat