For decades, the global supply chain was a model of hyper-efficiency. The "just-in-time" ideal minimized costs but maximized fragility. Today, that fragility is exposed. A delay at a port, a geopolitical tension, or a supplier's factory fire is no longer a manageable incident—it's a full-scale operational accident that halts your production, jeopardizes revenue, and damages client trust.

The question has shifted from if a disruption will occur to when. In this new reality, resilience is not a buzzword; it's your most critical competitive advantage.

So, how do we move from reactive firefighting to proactive fortress-building? At [Your Company Name], we build "crash-tested" hardware supply chains through three core principles:

1. True Diversification: Beyond Geography

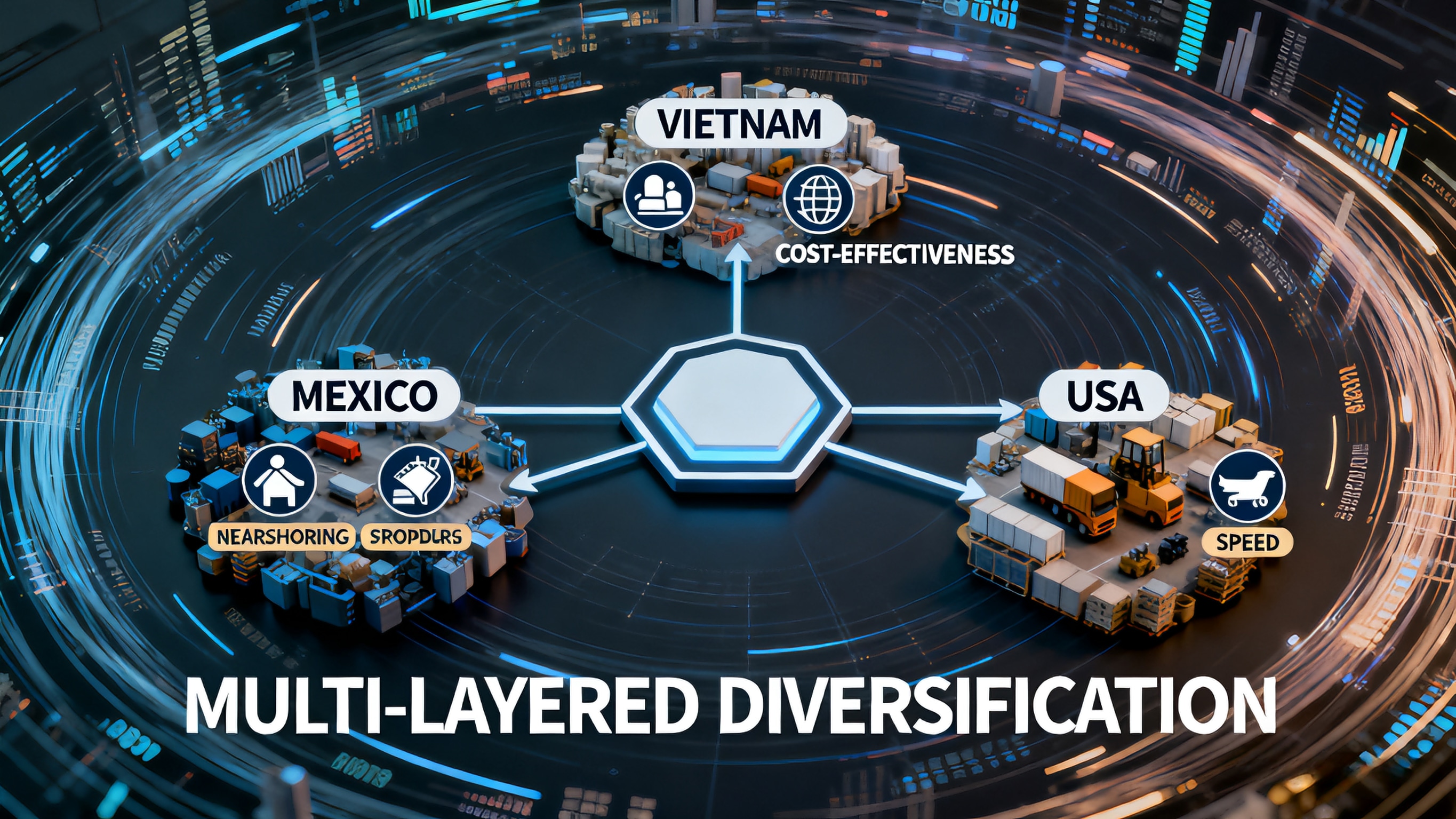

Diversification is more than just having a "China + 1" policy. It's a multi-layered strategy:

Geographic Spread: We maintain vetted manufacturing partners across strategic, non-overlapping regions (e.g., Mexico for nearshoring, Vietnam for cost-effectiveness, and domestic partners for speed). This ensures a regional crisis doesn't become your crisis.

Supplier Multi-Sourcing: For critical components, we pre-qualify multiple suppliers. This isn't about creating bidding wars; it's about creating instant optionality, allowing us to pivot in weeks, not months, when a primary supplier fails.

2. Intelligent Inventory: Your Strategic Shock Absorber

The goal is not to return to costly, bloated warehouses, but to be smart about risk. We treat strategic inventory as a calculated insurance policy.

We use data-driven models to identify the single points of failure in your Bill of Materials (BOM)—those long-lead-time, high-impact components. For these specific items, we strategically hold managed buffer stock. The cost of carrying this inventory is a fraction of the cost of a single production line shutdown.

3. Supplier Collaboration: From Transactional to Relational

A resilient chain is a transparent chain. We move beyond the purchase order to build true partnerships with our suppliers.

Shared Visibility: We create shared digital platforms for forecasts and inventory data, moving from surprises to predictability.

Early-Warning Systems: Strong relationships mean our suppliers alert us to potential disruptions early, giving us the most valuable asset in a crisis: time.

Joint Problem-Solving: When an issue arises, we don't assign blame; we huddle with suppliers (and you) to engineer a solution, transforming potential accidents into managed events.

The Bottom Line: Resilience is Your New ROI

Building a shock-resistant supply chain isn't an expense; it's a strategic investment that protects your:

Revenue & Market Share

Brand Reputation

Strategic Agility

The next disruption is a matter of time. The time to build your defenses is now.

Is your supply chain a story waiting to be told, or an accident waiting to happen? We help leading brands build the former. I'm curious to hear how you are building resilience—share your thoughts in the comments.

Contact: Tom

Phone: 86 18933248858

E-mail: tom@angxunmb.com

Whatsapp:86 18933248858

Add: Floor 301 401 501, Building 3, Huaguan Industrial Park,No.63, Zhangqi Road, Guixiang Community, Guanlan Street,Longhua District,Shenzhen,Guangdong,China

We chat