Accelerated Aging, Stress Loads, and Real-World Failure Prediction — Inside Our Reliability Lab

In the PC hardware world, failures rarely occur on day one.

They appear months—or years—after continuous thermal cycles, voltage fluctuations, and repeated high-load operations slowly push components to their physical limits.

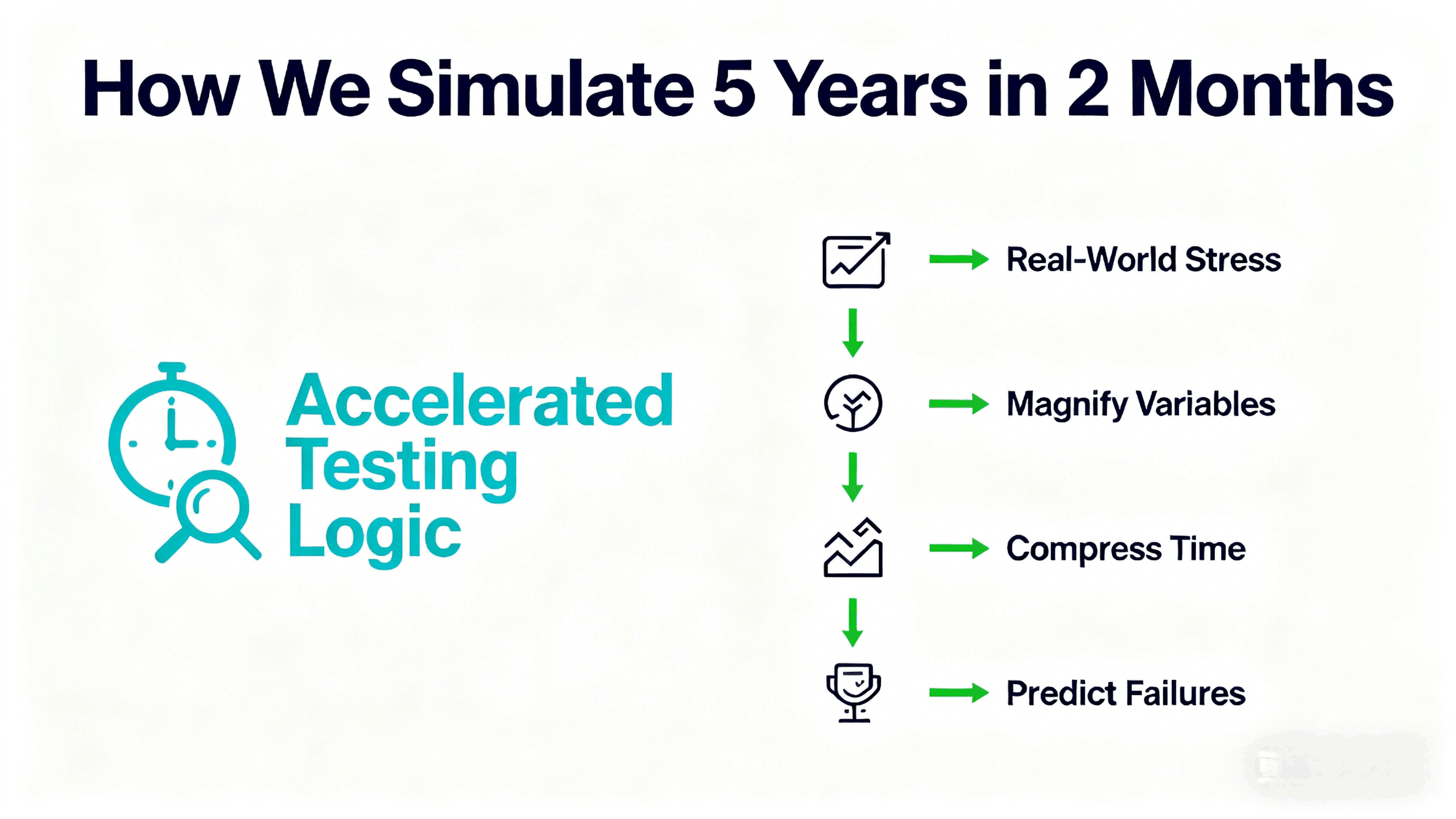

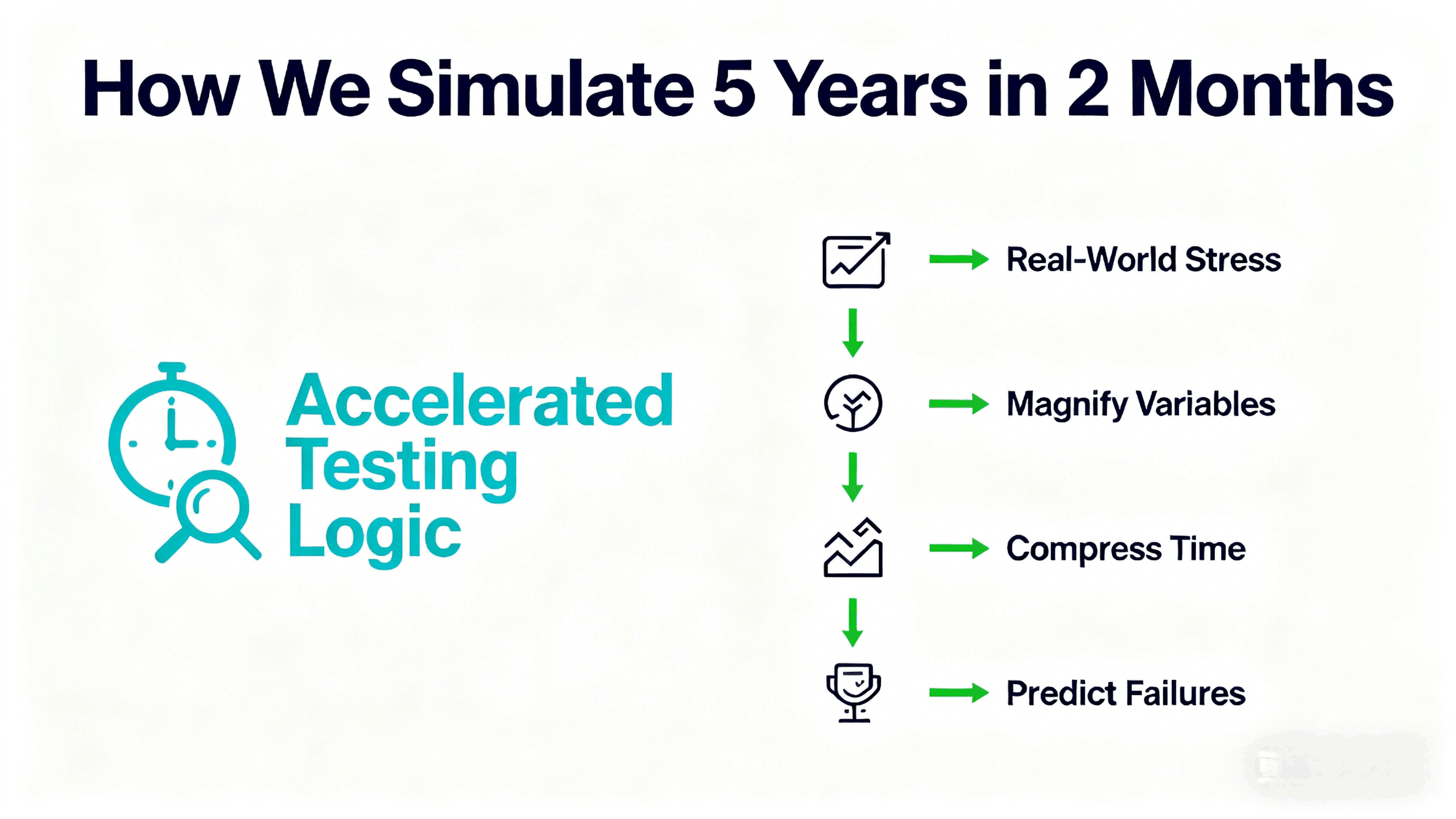

At Shenzhen Angxun Technology, we manufacture Intel, AMD, and industrial motherboards for global OEM and ODM partners. For long-term reliability, we don’t guess. We simulate the equivalent of five years of 24/7 real-world usage in just two months through a proven methodology known as Accelerated Reliability Testing.

This article breaks down the engineering science behind accelerated aging and how it helps predict real-world failures before products ship.

Why Accelerated Testing Matters

A motherboard running 24 hours a day experiences:

thousands of thermal expansion/contraction cycles

millions of power-state transitions

sustained VRM and capacitor stress

long-duration high-load CPU and memory activity

environmental variations (humidity, dust, airflow inconsistencies)

No datasheet alone can predict how all these variables interact.

Accelerated testing compresses years of stress into a manageable time window, giving engineering teams the data they need to prevent early-life failures, identify weak components, and refine system design.

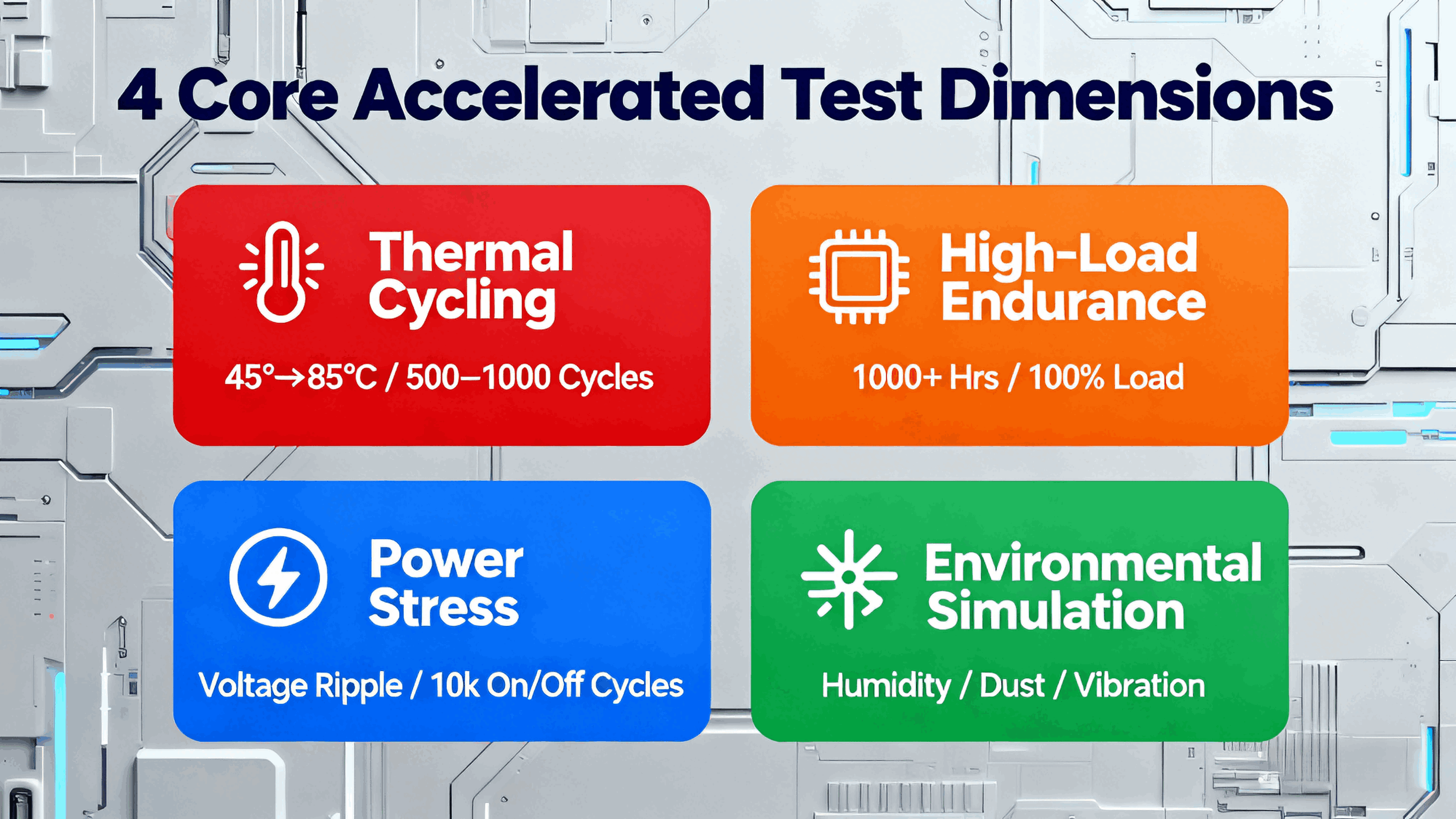

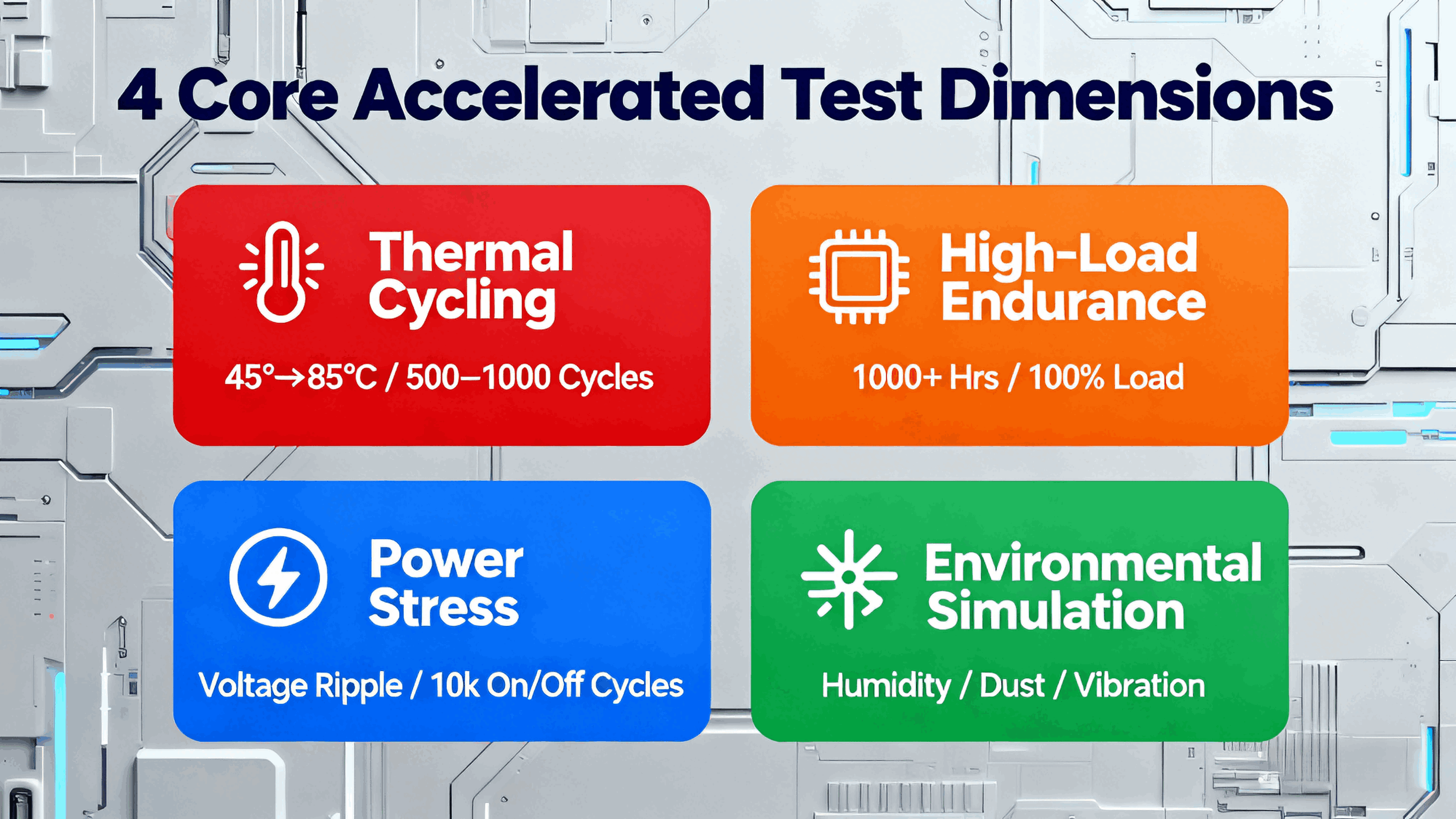

1. Thermal Cycling: The Silent Killer of Electronics

Most long-term failures are caused by temperature fatigue.

When a motherboard is repeatedly heated and cooled:

solder joints expand and contract

PCB copper layers deform microscopically

components shift under stress

insulation materials age faster

To simulate this, we run motherboards through:

✔ 45°C ↔ 85°C rapid thermal cycles

✔ 500–1,000 heating/cooling repetitions

✔ Continuous power-on during cycling

This stress exposes weak solder joints, insufficient PCB copper plating, or marginal components long before real customers experience problems.

2. High-Load Endurance: Sustaining 100% for Weeks

To replicate years of 24/7 server workloads, we run:

Prime95 and Cinebench CPU stress

Memtest and custom DDR load patterns

I/O flood tests on all PCIe, USB, SATA, and NVMe channels

Full-GPU or integrated graphics load

Network throughput saturation tests (1G/2.5G/10G)

A test cycle typically involves:

✔ 1,000+ hours of uninterrupted high-load operation

✔ CPU VRM temperature monitoring at 90°C+

✔ Power rail variance detection

This uncovers VRM overheating, power instability, poor thermal materials, and weak capacitors.

3. Power Stress and Electrical Overload Simulation

Real-world power isn't perfect.

Voltage sags, small spikes, ripple noise, and transient surges occur constantly—especially in industrial deployments.

We test using:

programmable power supplies

ripple noise injection

rapid on/off cycling (up to 10,000 cycles)

cold-start and hot-start switching

ESD (electrostatic discharge) shocks

This reveals issues with:

For example, Angxun motherboards use:

✔ independent CPU power-supply design

✔ zero-burning protection circuits

✔ dual safeguard modules for voltage and current stability

These aren’t marketing terms—they’re engineering decisions driven by stress-test results.

4. Environmental Simulation Beyond the Lab

Hardware often fails due to environment, not components.

So we test against:

We also run accelerated aging ovens to simulate long-term component wear on capacitors, polymers, and PCB dielectric materials.

What We Learn from 5-Year Simulation Data

Accelerated testing allows engineers to predict:

✔ Early-life failures (“infant mortality”)

✔ Component-level weaknesses

✔ VRM and capacitor lifetime degradation

✔ Real Tj (junction temperature) under heavy load

✔ PCB fatigue and solder aging

✔ Firmware-level stability over long durations

✔ Compatibility issues between CPU, RAM, storage, and NICs under stress

These insights directly shape production decisions—component selection, PCB layer thickness, cooling design, and BIOS tuning.

Why We Invest So Heavily in Reliability Testing

As a manufacturer serving system integrators, OEM brands, and industrial clients:

A single field failure can cost more than an entire batch of lab tests.

A stable motherboard reduces RMA rate and boosts brand trust.

System integrators rely on predictable, long-term reliability.

By simulating five years of operation in two months, we eliminate surprises and deliver motherboards engineered for stability—not just “good enough” performance.

About Shenzhen Angxun Technology

Established in 2003, Angxun is a high-tech manufacturing company with:

10,000 m² factory area

500+ staff

5 SMT production lines

High-precision SPI, AOI, ICT, and aging labs

300,000+ monthly motherboard capacity

We specialize in:

Our engineering philosophy is simple:

If it’s not stable under stress, it’s not ready for the market.