In the hardware industry, trust is no longer built by glossy brochures or well-polished presentations.

Trust is built when a supplier is confident enough to open every door—literally.

At Shenzhen Angxun Technology Co., Ltd., we actively invite our OEM/ODM partners to audit our facilities, review our processes, and evaluate our supply chain from end to end. For us, transparency is not a marketing slogan—it is a strategic foundation for long-term cooperation.

Here is why we believe transparency is the most efficient path to strategic trust.

1. Transparency Replaces Guesswork With Evidence

Brands today are under increasing pressure: product reliability, supply chain resilience, environmental responsibility, and compliance risks all tie directly to the manufacturer they choose.

By opening our factory doors, we allow customers to see—firsthand—how we operate:

How we source raw materials

How we control quality at each stage

How we ensure engineering consistency across batches

How we make long-term component decisions for lifecycle stability

Nothing builds confidence faster than giving customers full visibility.

2. What an Angxun Supply Chain Audit Looks Like

Over the past 24 years, we’ve refined a supplier audit workflow that global brands find both rigorous and reassuring.

Step 1 — Manufacturing Environment Inspection

Customers walk through our 10,000 m² facility, including:

Five SMT production lines with high-speed placement

High-precision SPI and AOI testing systems

DIP lines, wave soldering, automated assembly

Thermal, aging, and reliability testing areas

This allows customers to assess equipment capability, maintenance discipline, and production throughput.

Step 2 — Quality Control and Traceability Review

Auditors examine:

Incoming material inspection standards

PCB and component traceability

Soldering quality criteria

Reliability and stress-testing processes

RMA analytics and corrective action mechanisms

Our ability to achieve 300,000+ motherboards per month is only meaningful when paired with traceable, consistent quality.

Step 3 — Engineering & R&D Capability Evaluation

Customers meet with our 50+ R&D engineers, reviewing:

Electrical and PCB design workflows

BIOS/firmware development

DFM/DFT methodologies

Thermal simulation and mechanical design

Compatibility verification processes

This ensures that we are not just a factory—but a technical partner capable of co-design.

Step 4 — Supply Chain & Compliance Verification

We demonstrate:

CE / RoHS / FCC / ISO certifications

Environmental material management

Long-term component sourcing strategies

Vendor qualification and periodic re-evaluation workflows

For many brands, sustainability and compliance are now critical decision factors.

Step 5 — Live Production Audit

Customers observe real-time builds:

This gives them a true, unfiltered understanding of consistency and craft.

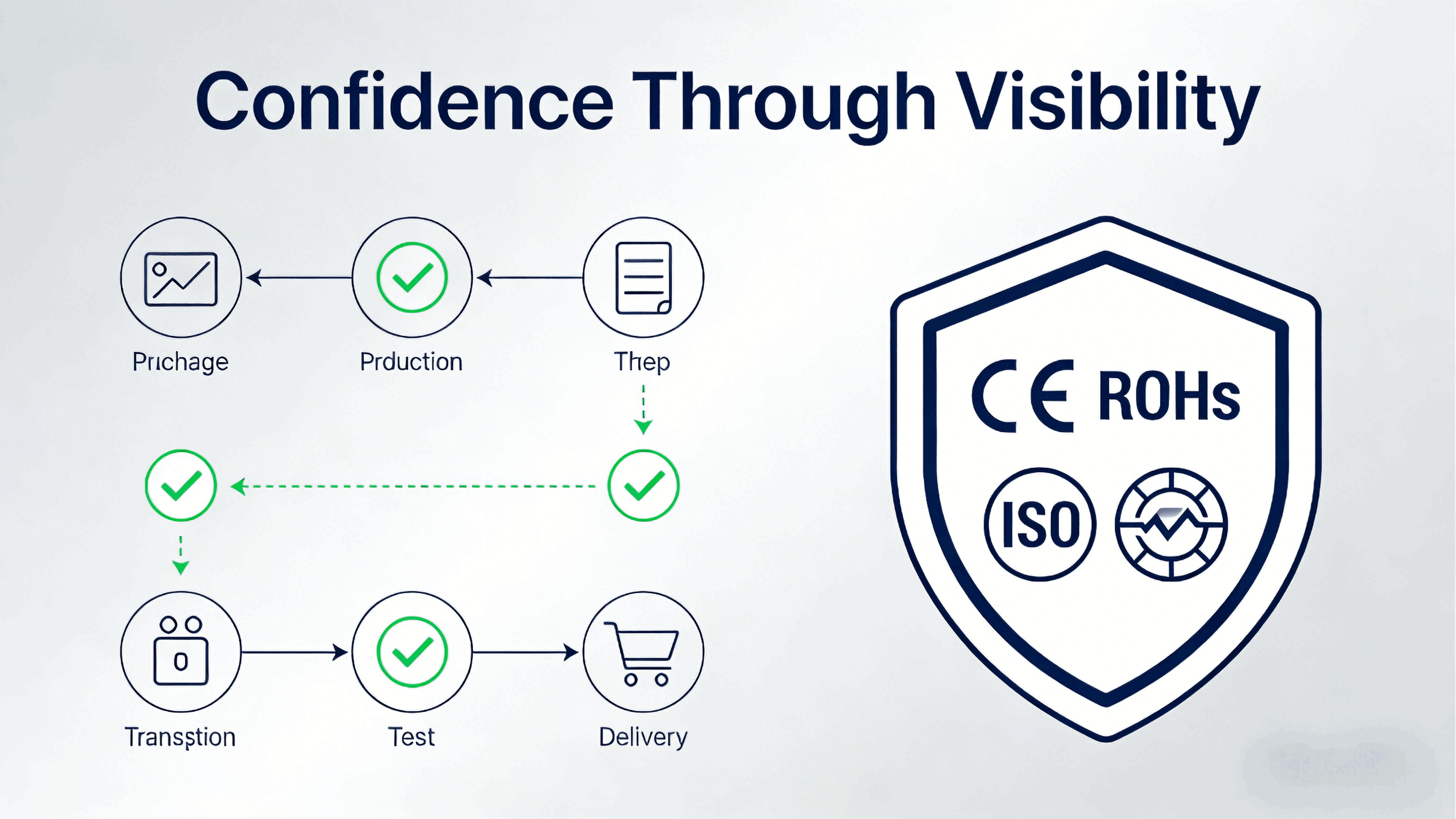

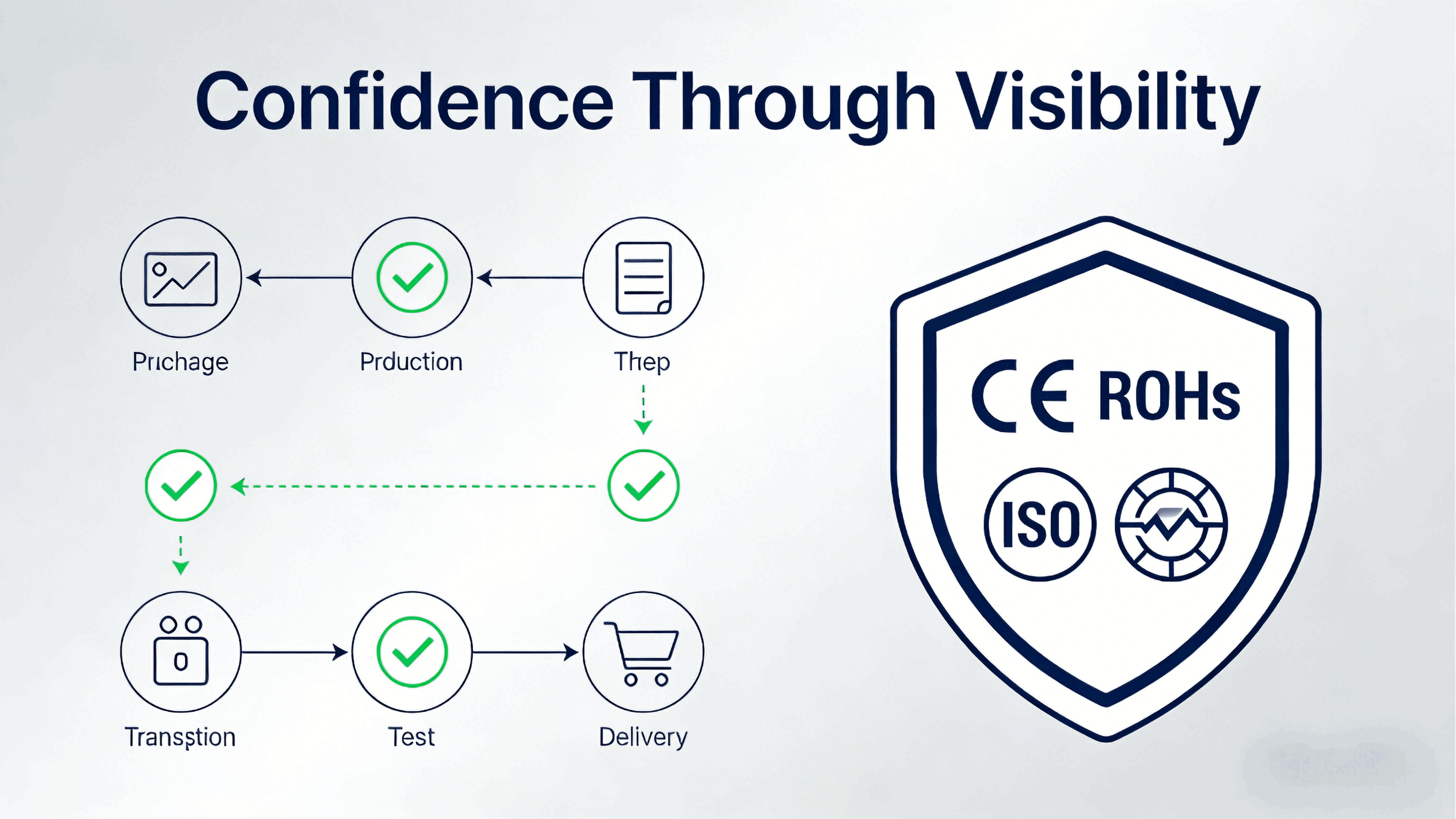

3. What We Mean by “Confidence Through Openness”

We can open our supply chain because we genuinely believe in the strengths of our products:

Product-Level Advantages

Aluminum-based thermal design for effective heat dissipation

All-solid capacitors for long life and stability

PCB copper plating for better power integrity

Independent CPU power stage for heavy workloads

Zero-burning protection circuits

Dual safety voltage/current stabilization design

Company-Level Advantages

24 years of OEM/ODM experience

Environmentally responsible production

Full CE, RoHS, FCC, ISO certifications

Strong R&D backbone

Fast delivery and reliable logistics

Guaranteed after-sales technical support

This makes transparency not risky—but powerful.

4. Why Brands Prefer Transparent Manufacturers

When partners can freely audit a factory, the relationship quickly transforms:

In an industry where hidden problems often surface too late, transparency is the ultimate competitive advantage.

5. Our Invitation to Global Brands

If you want a manufacturing partner who:

Welcomes audits,

Encourages technical discussions,

Shares data openly,

Provides engineering visibility, and

Builds products with durability, safety, and performance in mind—

Then our doors are always open.

Shenzhen Angxun Technology Co., Ltd.

Your transparent, engineering-driven OEM/ODM partner for Intel/AMD motherboards, industrial PCs, Mini PCs, laptops, and more.