Most IT leaders have learned this lesson the hard way:

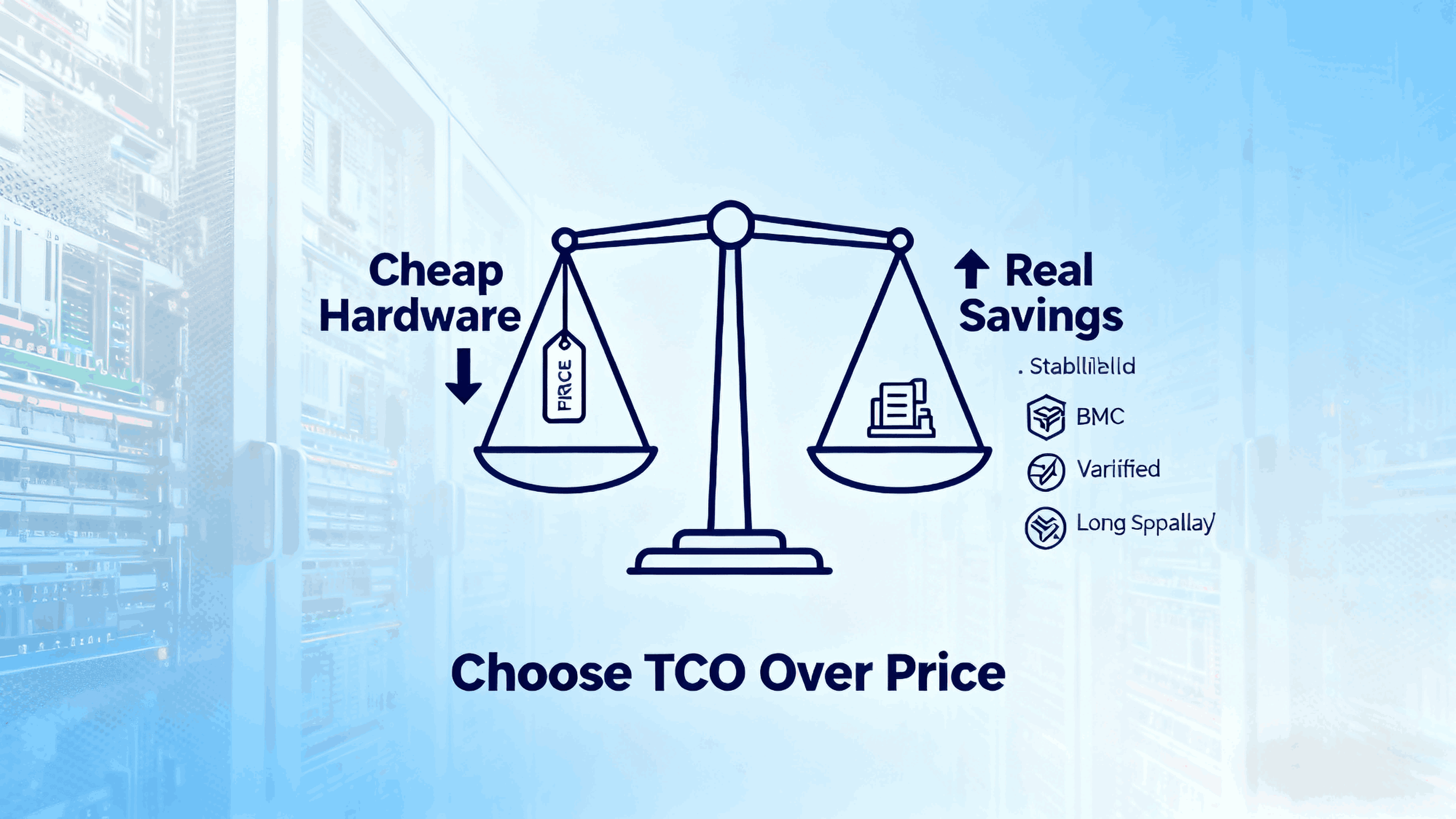

A low purchase price is not the same as a low total cost.

Especially in the world of white-label and OEM servers.

In the past 18 months, we’ve spoken with dozens of U.S. system integrators and MSPs who shared the same frustration:

“The units were cheap… until the failures started.”

If you want predictable margins, stable deployments, and fewer late-night emergencies, you must look beyond the sticker price and calculate true Total Cost of Ownership (TCO).

Here are the hidden cost drivers that matter far more than the initial quote.

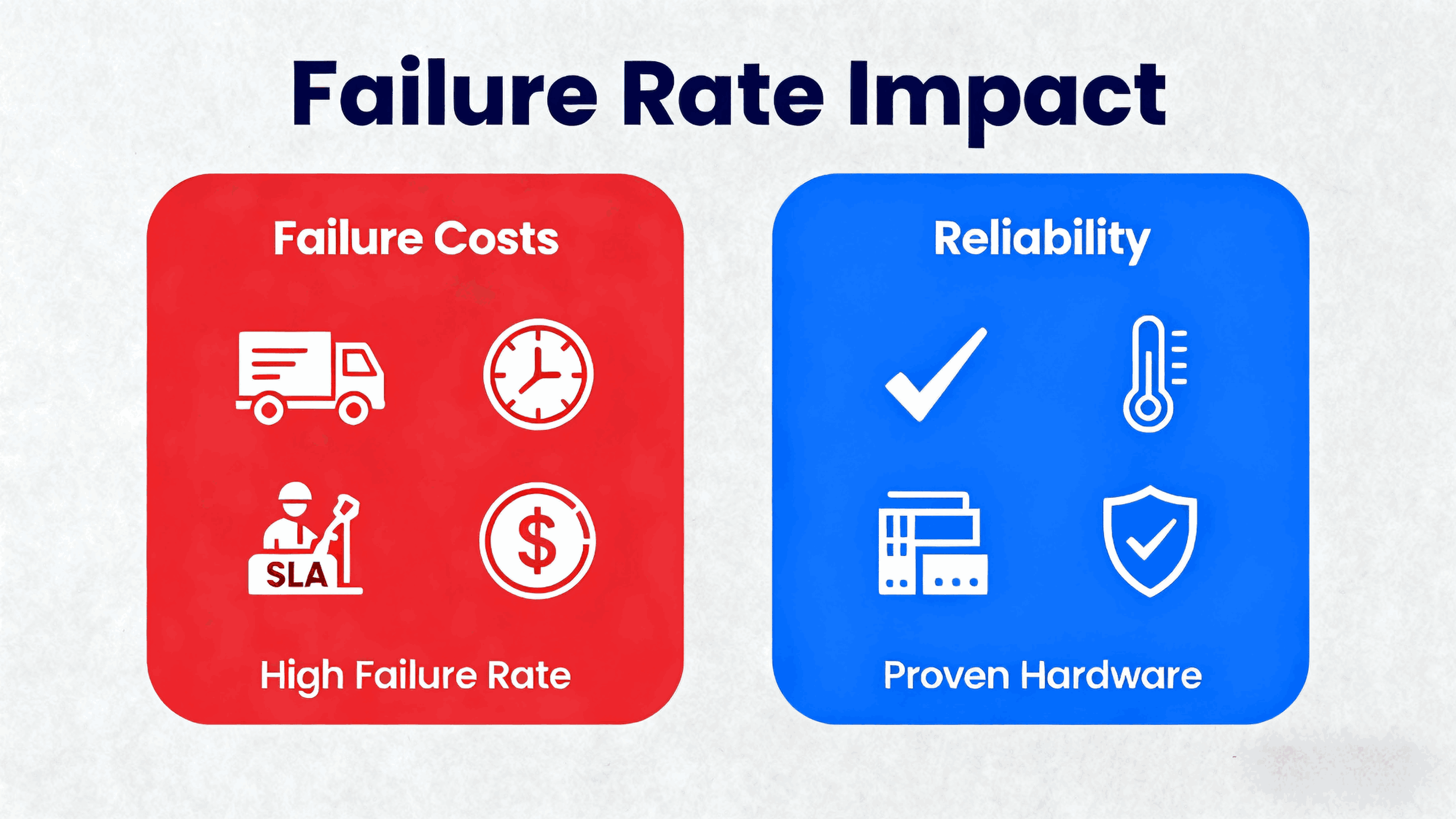

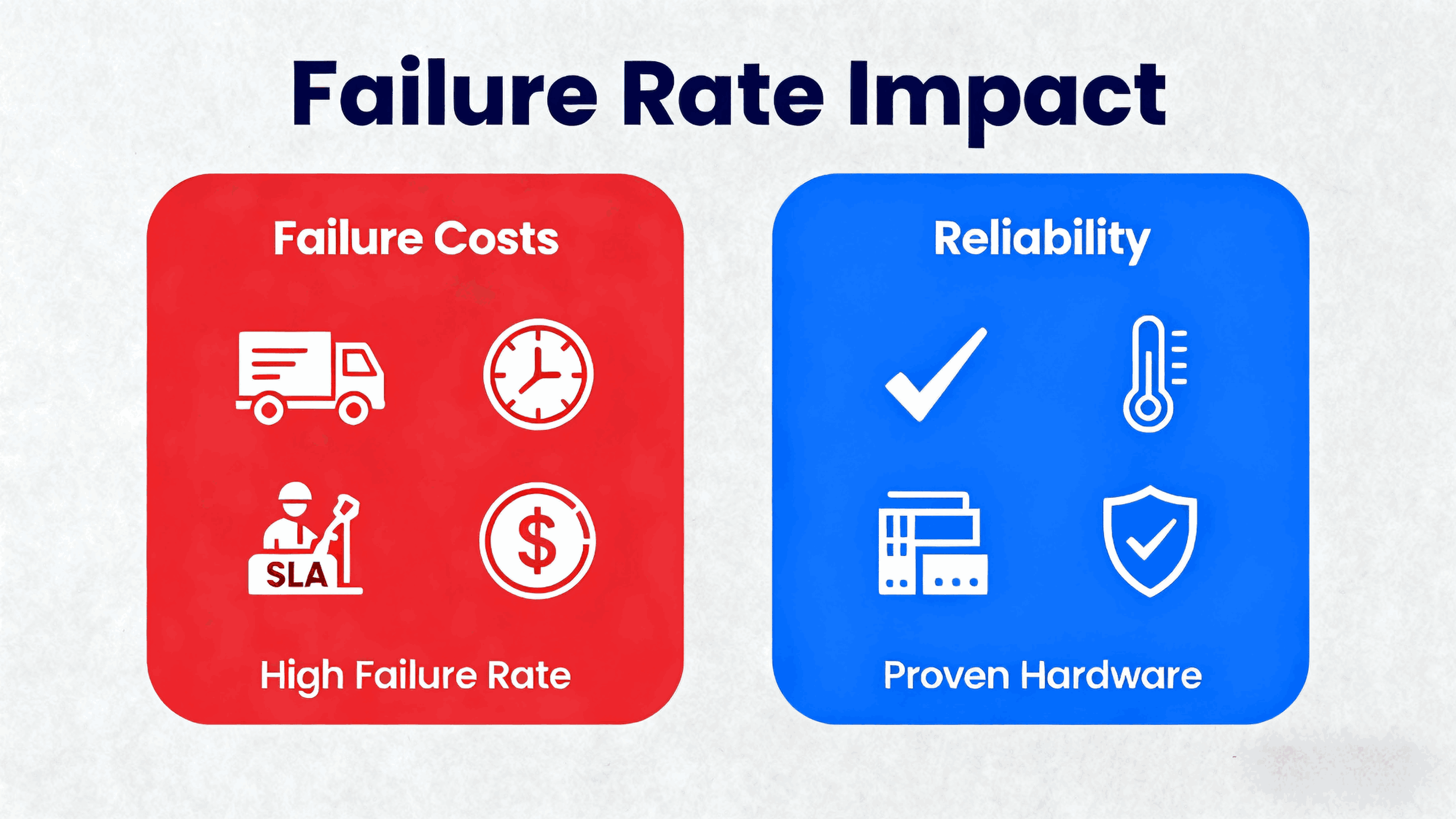

1. The Failure Rate Multiplier: The Most Expensive Cost Is Downtime

A server that costs $80 less upfront can easily cost 20× more when field failures begin.

Hidden Costs of High Failure Rates:

Truck rolls & onsite replacements

RMA logistics and customer service hours

SLA penalty payouts

Lost customer confidence

Emergency resource allocation (usually nights & weekends)

Even a 1–2% difference in hardware failure rate can translate into thousands of dollars per year for MSPs with active field deployments.

This is why professional vendors invest heavily in:

✔ Long-cycle reliability testing (thermal, power, workload aging)

✔ Component-level compatibility validation

✔ Stable supply chains for long-term consistency

Cheap servers skip most of this.

2. Power Consumption: The Silent Profit Killer

Energy usage is now one of the top TCO factors in North America.

A server that consumes 10–15W more under typical workloads can add up to:

$40–$70 per server per year in electricity

Higher cooling requirements

Reduced rack density, which increases long-term CAPEX

Multiply that across a few hundred units, and the “cheap” purchase suddenly becomes a very expensive mistake.

3. Firmware, BMC, and Manageability: The Hidden Labor Tax

Most low-end white-label hardware cuts corners in the system management layer—particularly the BMC (Baseboard Management Controller).

Here’s what that means for real-world operations:

Remote KVM dropouts mid-session

Unstable sensor readings

Inconsistent IPMI/Redfish implementations

Firmware that can’t be updated without onsite intervention

Security vulnerabilities that never get patched

An unstable BMC adds hours of manual labor per server per year, which is the most expensive cost of all.

High-quality vendors offer:

✔ Enterprise-grade BMC

✔ Regular firmware updates

✔ Full Redfish/IPMI compliance

✔ Predictable management behavior across product generations

This directly reduces operational cost and increases deployment efficiency.

4. Component Compatibility: Where “Cheap” Becomes Chaotic

This is one of the biggest hidden risks.

Many low-cost server boards are not validated across:

When a compatibility conflict hits, the cost is enormous:

Delayed customer deployments

Hours of trial-and-error debugging

Lost revenue from project delays

Emergency switching to more expensive parts

A pre-validated hardware matrix eliminates 80–90% of these incidents before deployment.

5. Long-Term Supply Guarantees: The Insurance Policy You Didn’t Know You Needed

Many SIs and MSPs get burned by conditions like these:

CPU no longer available

A board revision silently changes VRM or chipset behavior

Same SKU but different BOM (common in “cheap” factories)

No last-time-buy window

No replacement plan for EOL parts

The result?

You cannot expand your customer’s deployment later—hurting your brand, not the factory’s.

This is why reputable hardware vendors commit to:

✔ Fixed BOM

✔ Multi-year supply visibility

✔ Planned EOL roadmap

✔ Drop-in compatible successor models

✔ Advance notice for lifecycle transitions

This protects your business model.

Cheap Hardware Is Not Actually Cheap

When you add the numbers, “low-cost servers” often result in:

Hidden Cost Type | Impact |

Failure rate | Highest TCO impact; reputational damage |

Power usage | Recurring annual cost; scales with deployment size |

Firmware & BMC issues | Labor-intensive; reduces operational efficiency |

Compatibility problems | Delayed projects; support overhead |

Short lifecycle | Breaks multi-year contracts; kills standardization |

In contrast, hardware with:

delivers the REAL savings—by reducing support, downtime, and operational burden.

Final Thought: Choose Based on TCO, Not Unit Price

For U.S. system integrators, MSPs, and OEM customers, the lesson is clear:

You don’t win by buying the cheapest hardware.

You win by eliminating the hidden costs that destroy your margins.

If you want predictable deployments, lower support cost, and a partner that understands long-term hardware lifecycle, choose vendors who invest in quality—not shortcuts.