The brutal truth about industrial computing: if your hardware can't handle extreme temperatures, it's just expensive junk waiting to fail.

We learned this lesson the hard way when a batch of "industrial" motherboards started failing in Middle Eastern oil rigs. The components met specifications, the testing seemed adequate, but reality proved merciless. Here's what years of designing AMD-based industrial motherboards, panel PCs, and embedded systems have taught us about true wide-temperature operation.

The Component Selection Minefield

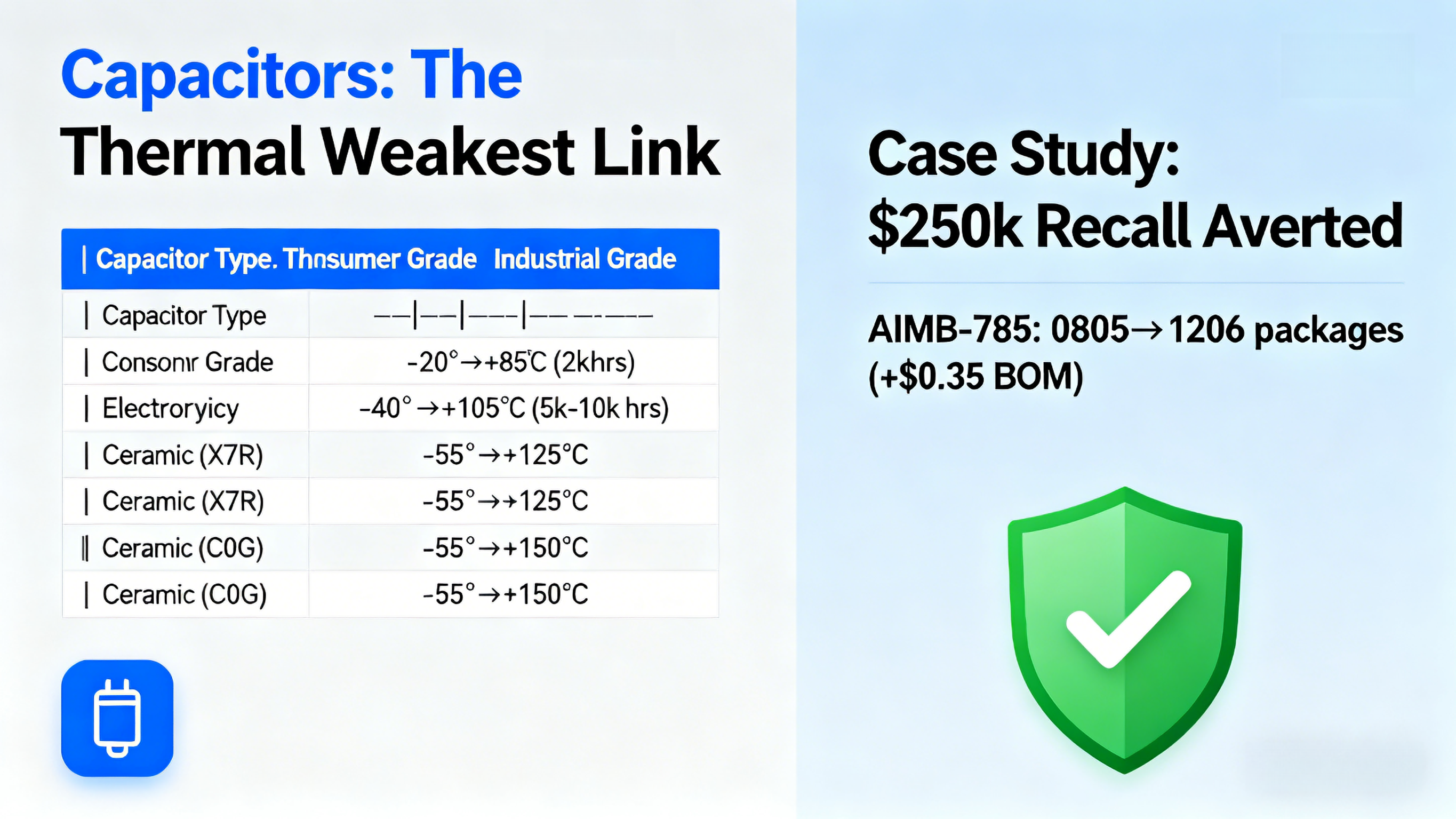

Capacitors: The Thermal Weakest Link

Most hardware failures in extreme temperatures trace back to capacitors. The difference between consumer and industrial components is stark:

Electrolytic Capacitors:

Consumer grade: -20°C to +85°C (2,000-hour lifespan)

Industrial grade: -40°C to +105°C (5,000-10,000-hour lifespan)

Cost difference: 3-5x, but prevents 80% of field failures

Ceramic Capacistors:

X7R: -55°C to +125°C (solid choice)

X5R: -55°C to +85°C (avoid for wide-temperature)

C0G/NP0: -55°C to +150°C (premium, but expensive)

Real Case: The $250,000 Recall That Didn't Happen

We caught a capacitor issue during validation of our AIMB-785 industrial motherboard. Standard 0805 capacitors cracked during thermal shock testing between -40°C and 85°C. The fix? Switching to 1206 packages with flexible termination - adding $0.35 to BOM cost but preventing almost certain field failures.

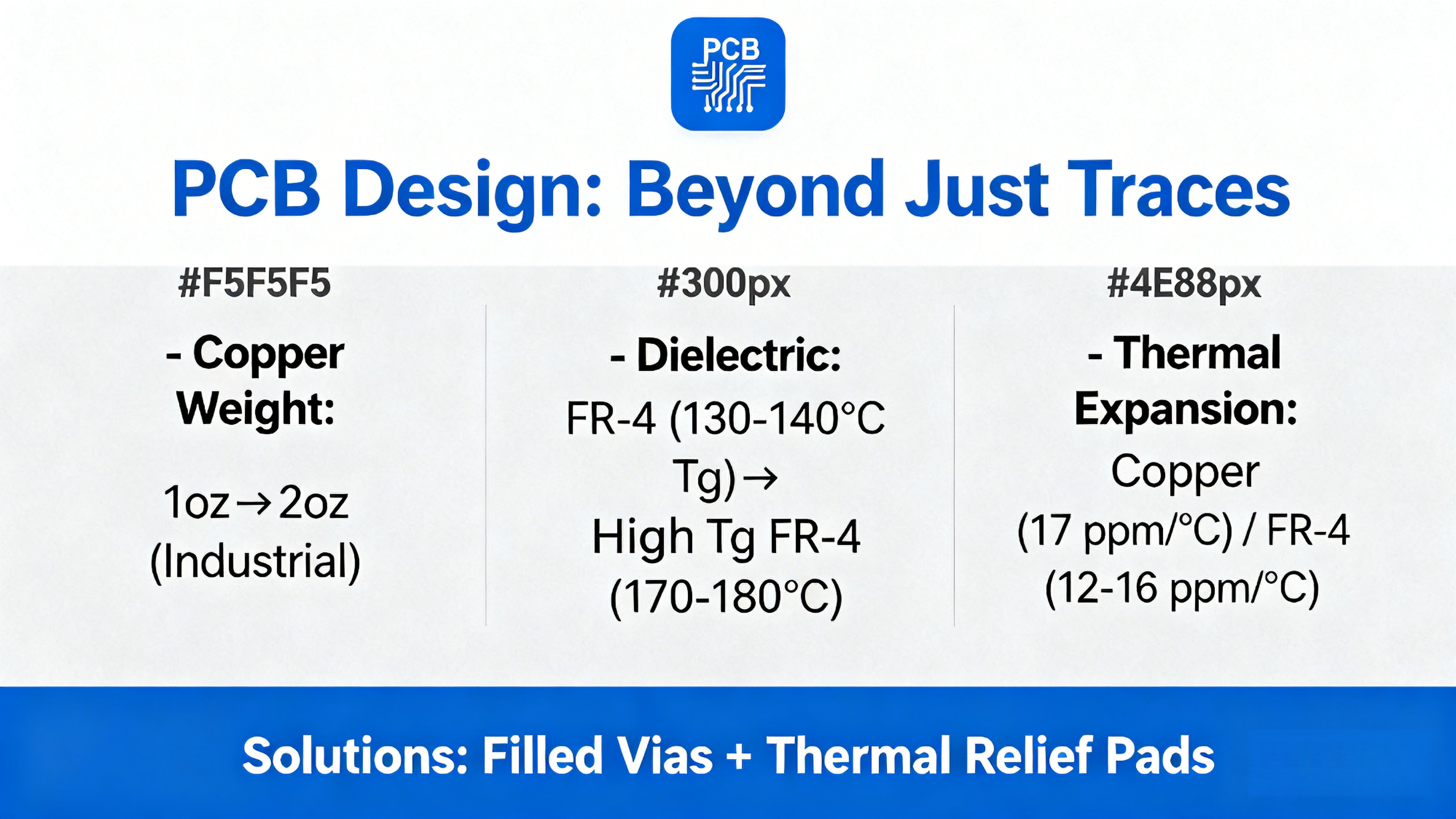

PCB Design: More Than Just Traces

Copper Weight Matters

Standard PCBs: 1oz copper

Industrial wide-temp: 2oz copper minimum

Benefit: Better heat distribution, reduced thermal stress

Dielectric Material Selection

FR-4 Standard: Tg 130-140°C

FR-4 High Tg: Tg 170-180°C (essential for wide-temp)

Polyimide: Tg >250°C (for extreme applications)

The Thermal Expansion Trap

Different materials expand at different rates:

Copper CTE: 17 ppm/°C

FR-4 CTE: 12-16 ppm/°C (in-plane)

Component CTE: 6-8 ppm/°C

This mismatch causes solder joint cracks during thermal cycling. Our solution? Using filled vias and adding thermal relief pads.

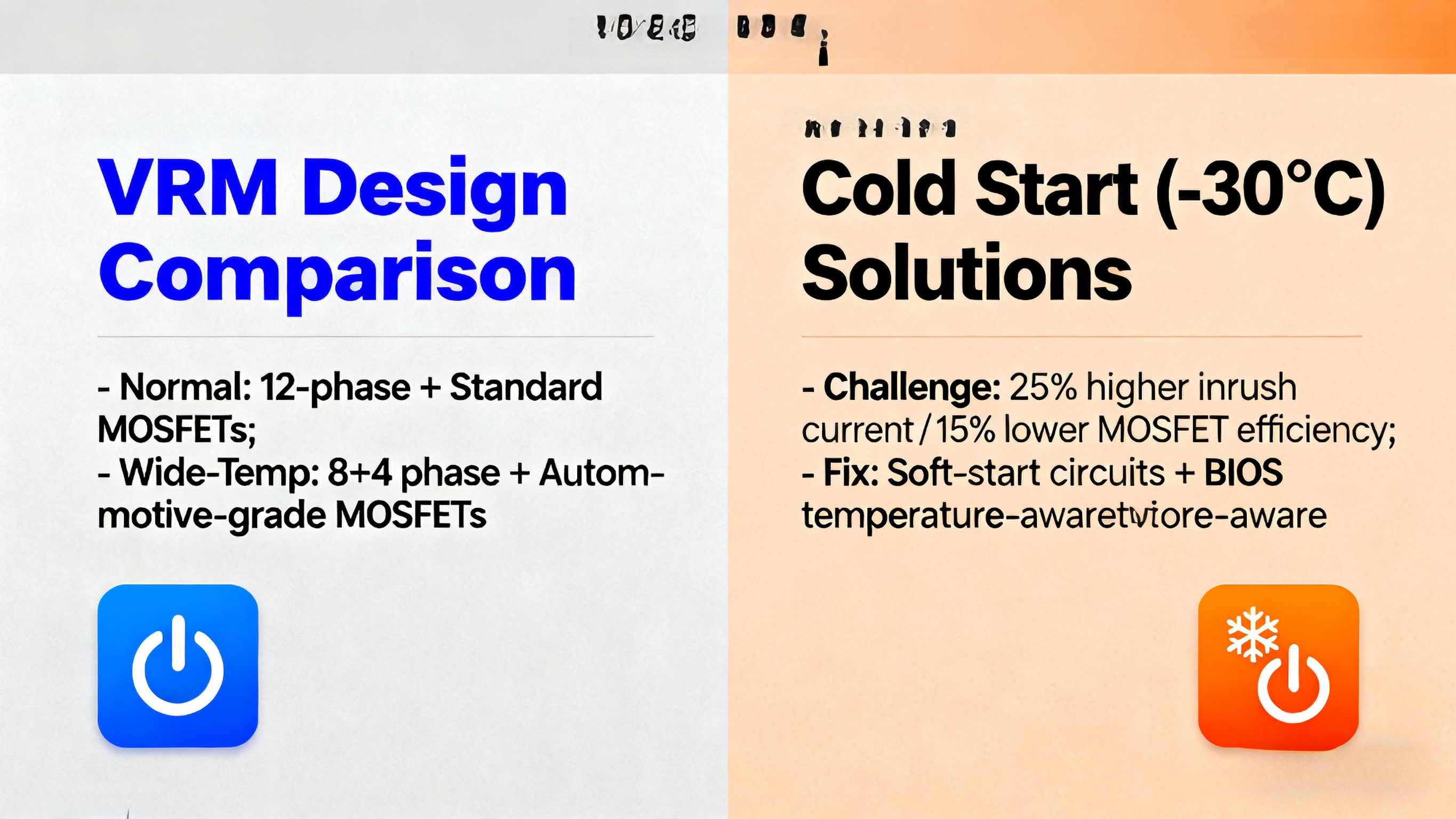

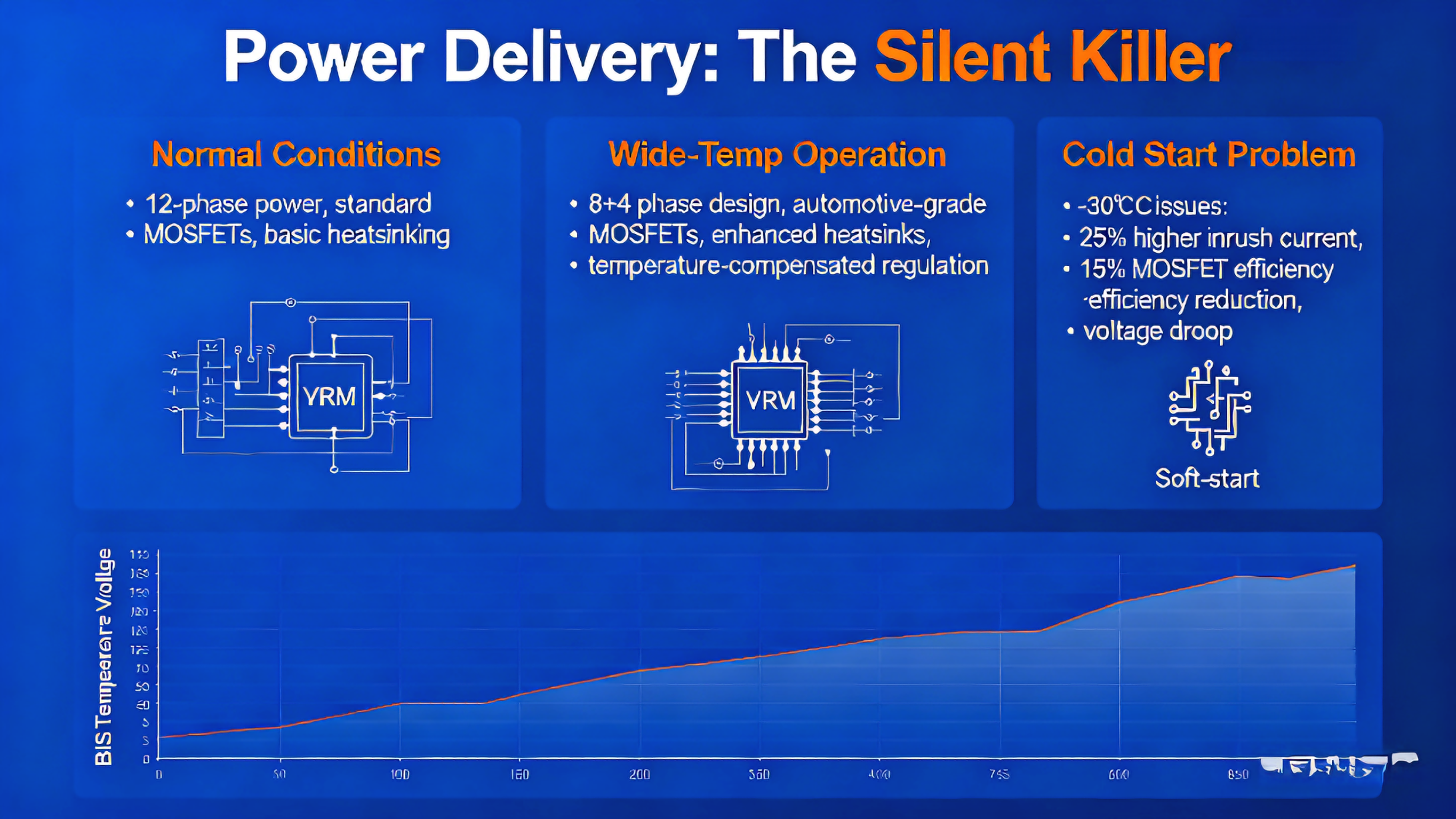

Power Delivery: The Silent Killer

VRM Design for Extreme Conditions

A typical AMD Ryzen Embedded V3000 series industrial motherboard requires:

Normal Conditions:

12-phase power design

Standard MOSFETs

Basic heatsinking

Wide-Temperature Operation:

8+4 phase design (more stable under thermal stress)

Automotive-grade MOSFETs

Enhanced heatsinks with thermal pads

Temperature-compensated voltage regulation

The Cold Start Problem

At -30°C, we observed:

25% higher inrush current

15% reduction in MOSFET efficiency

Voltage droop during initial power-on

Solution: Implementing soft-start circuits and temperature-aware voltage scaling in BIOS.

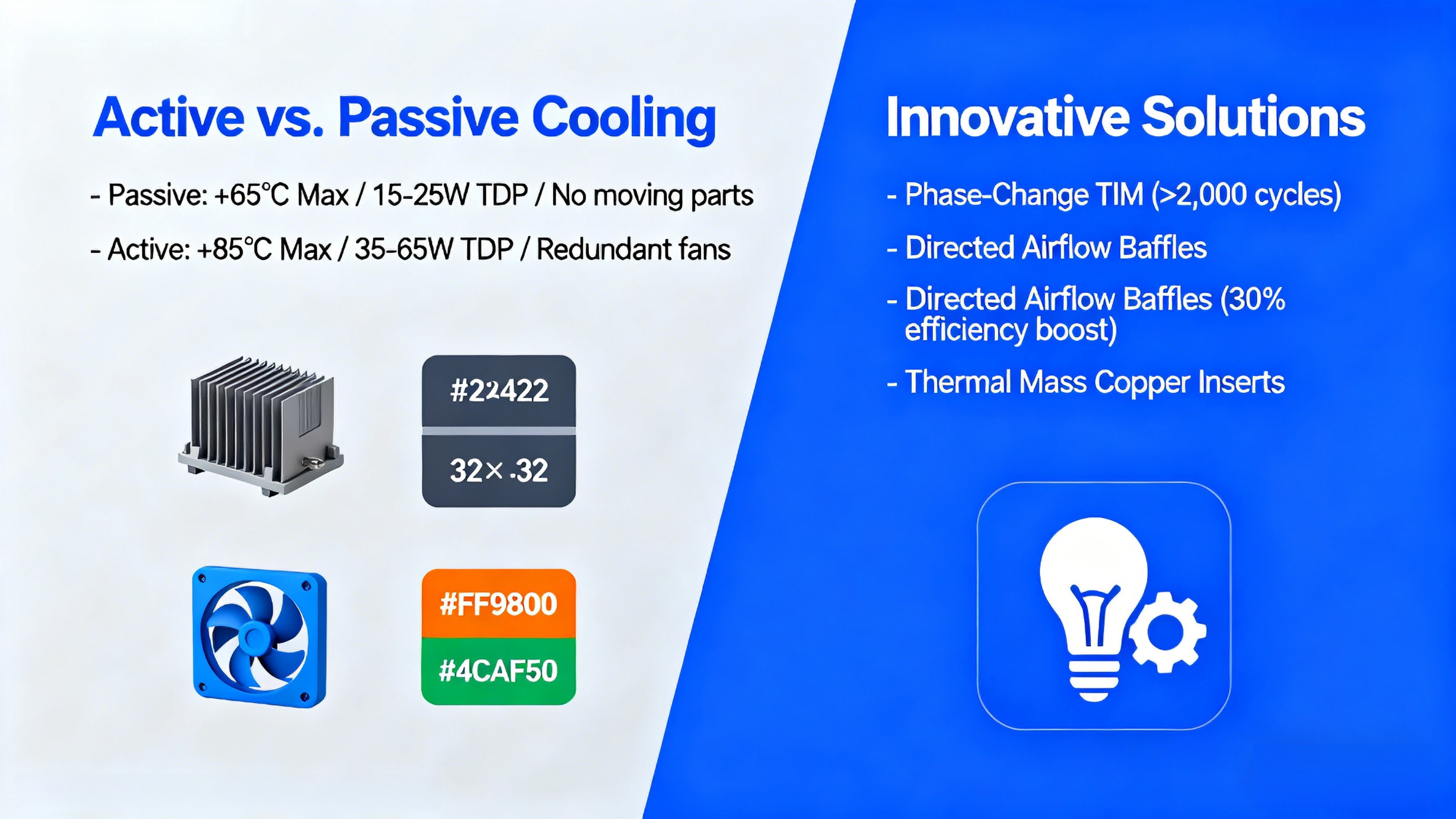

Thermal Management: Beyond Heatsinks

Active vs. Passive Cooling

Our testing revealed surprising results:

Passive Cooling (Industrial Panel PCs):

Reliable to +65°C ambient

No moving parts (higher reliability)

Limited to 15-25W TDP processors

Active Cooling (Industrial Motherboards):

Reliable to +85°C ambient

Fan failure risk, but redundant designs possible

Supports 35-65W TDP processors

Innovative Solutions We've Implemented

Phase-Change Thermal Interface Materials

Standard thermal paste fails after 500 thermal cycles

Phase-change materials maintain performance beyond 2,000 cycles

Directed Airflow Baffles

30% improvement in cooling efficiency

Prevents dust accumulation

Thermal Mass Integration

Adding strategically placed copper inserts

Smoothens temperature transitions

The Validation Gauntlet

Our 5-Stage Testing Protocol

Thermal Cycling

-40°C to +85°C, 30-minute dwell times

1,000 cycles minimum (simulates 5+ years)

Monitoring for solder cracks, component drift

Temperature-Humidity-Bias

85°C/85% relative humidity

Continuous operation under load

1,000-hour duration

High-Temperature Operating Life

125°C ambient temperature

168 hours continuous operation

Accelerated lifespan testing

Thermal Shock

-40°C to +85°C in <30 seconds

500 cycles minimum

Most revealing test for material compatibility

Real-World Simulation

Desert testing: +55°C direct sunlight

Industrial freezer testing: -40°C with rapid cycling

Vibration + temperature combined stress

Case Study: Mining Operation Success

The Challenge:

AMD-based mining control systems failing in Canadian operations:

Winter temperatures: -35°C

Summer temperatures: +40°C

24/7 operation requirement

Dust and vibration present

Our Solution:

Modified AIMB-582 industrial motherboard:

Selected automotive-grade power components

Implemented 2oz copper PCB with high-Tg material

Added conformal coating for humidity protection

Used wide-temperature DDR5 modules

Implemented temperature-aware fan control

Results:

18 months continuous operation

Zero temperature-related failures

30% reduction in maintenance costs

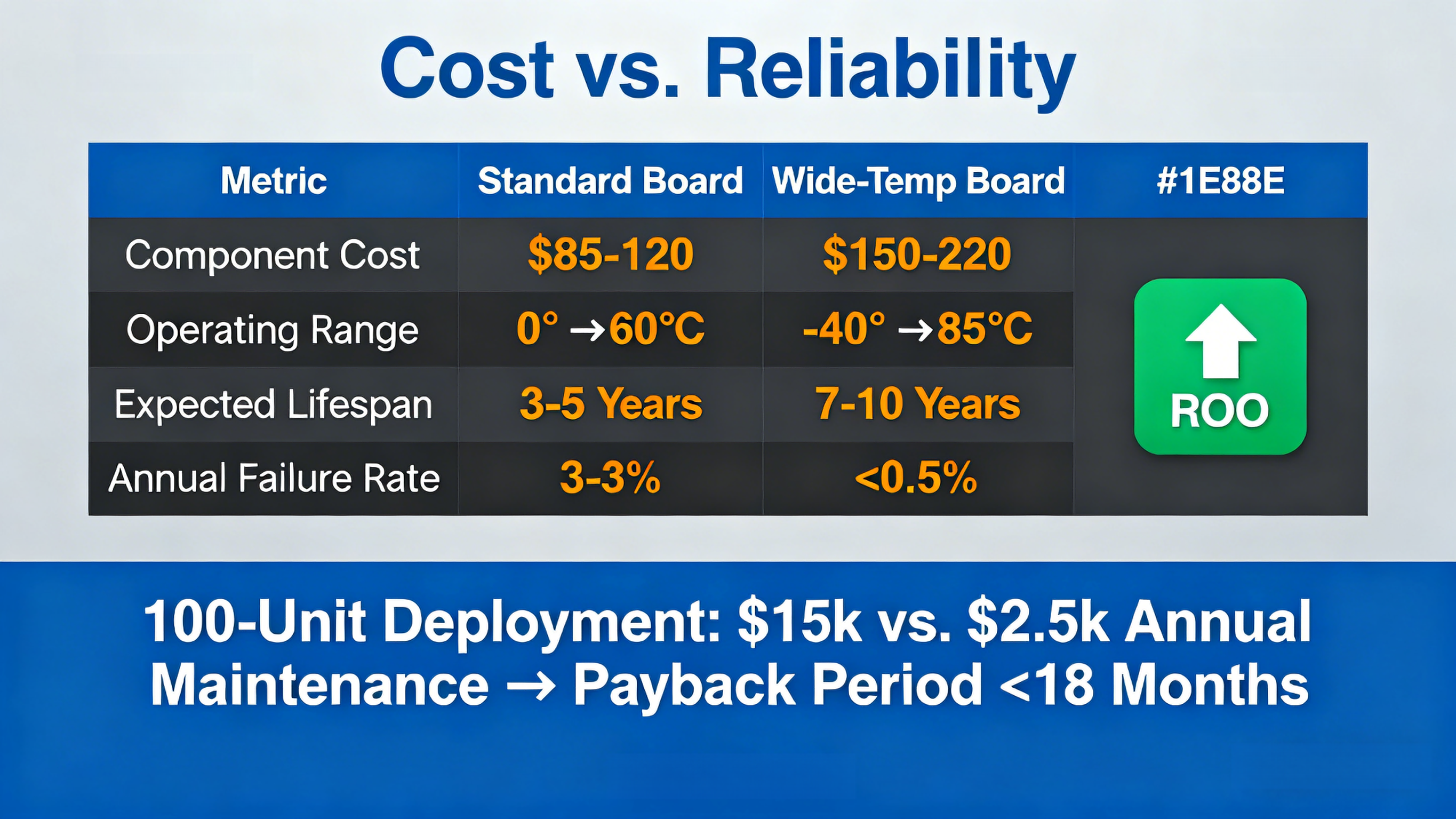

Cost vs. Reliability: The Business Case

Standard Industrial Motherboard:

Component cost: $85-120

Operating range: 0°C to 60°C

Expected lifespan: 3-5 years

Failure rate: 3-5% annually in harsh environments

Wide-Temperature Industrial Motherboard:

Component cost: $150-220

Operating range: -40°C to 85°C

Expected lifespan: 7-10 years

Failure rate: <0.5% annually in harsh environments

ROI Calculation:

For a 100-unit deployment in harsh environment:

Standard boards: $15,000 annual maintenance

Wide-temp boards: $2,500 annual maintenance

Payback period: <18 months

Implementation Guide

For System Integrators:

Verify, Don't Trust

Demand test reports, not just specifications

Require validation data for your specific temperature range

Audit supplier testing facilities

Consider the Total Environment

Solar loading can add 20°C to ambient temperatures

Enclosure design affects internal temperatures

Airflow restrictions impact cooling efficiency

Plan for Real-World Conditions

Test in actual deployment environments

Monitor early deployments closely

Maintain spares strategically

The Bottom Line

Wide-temperature design isn't about adding a few industrial components. It's a holistic approach that considers:

Component selection based on actual performance, not just datasheets

PCB design optimized for thermal stress management

Power delivery designed for extreme condition stability

Rigorous validation that simulates real-world conditions

The companies that get this right aren't just selling hardware—they're delivering reliability that becomes the foundation of their customers' operations.

We design and manufacture AMD-based industrial computing solutions that survive where others fail. Our industrial motherboards, panel PCs, and embedded systems are proven in applications from desert mining to arctic research. Contact us to discuss your extreme environment computing requirements.

Contact: Tom

Phone: 86 18933248858

E-mail: tom@angxunmb.com

Whatsapp:86 18933248858

Add: Floor 301 401 501, Building 3, Huaguan Industrial Park,No.63, Zhangqi Road, Guixiang Community, Guanlan Street,Longhua District,Shenzhen,Guangdong,China

We chat