In the industrial, server, and embedded computing world, reliability is not a feature—it's a requirement.

A motherboard that fails in a data center, vehicle, kiosk, factory floor, or medical system does not simply “break”—it interrupts revenue, damages brand reputation, and may even put safety at risk.

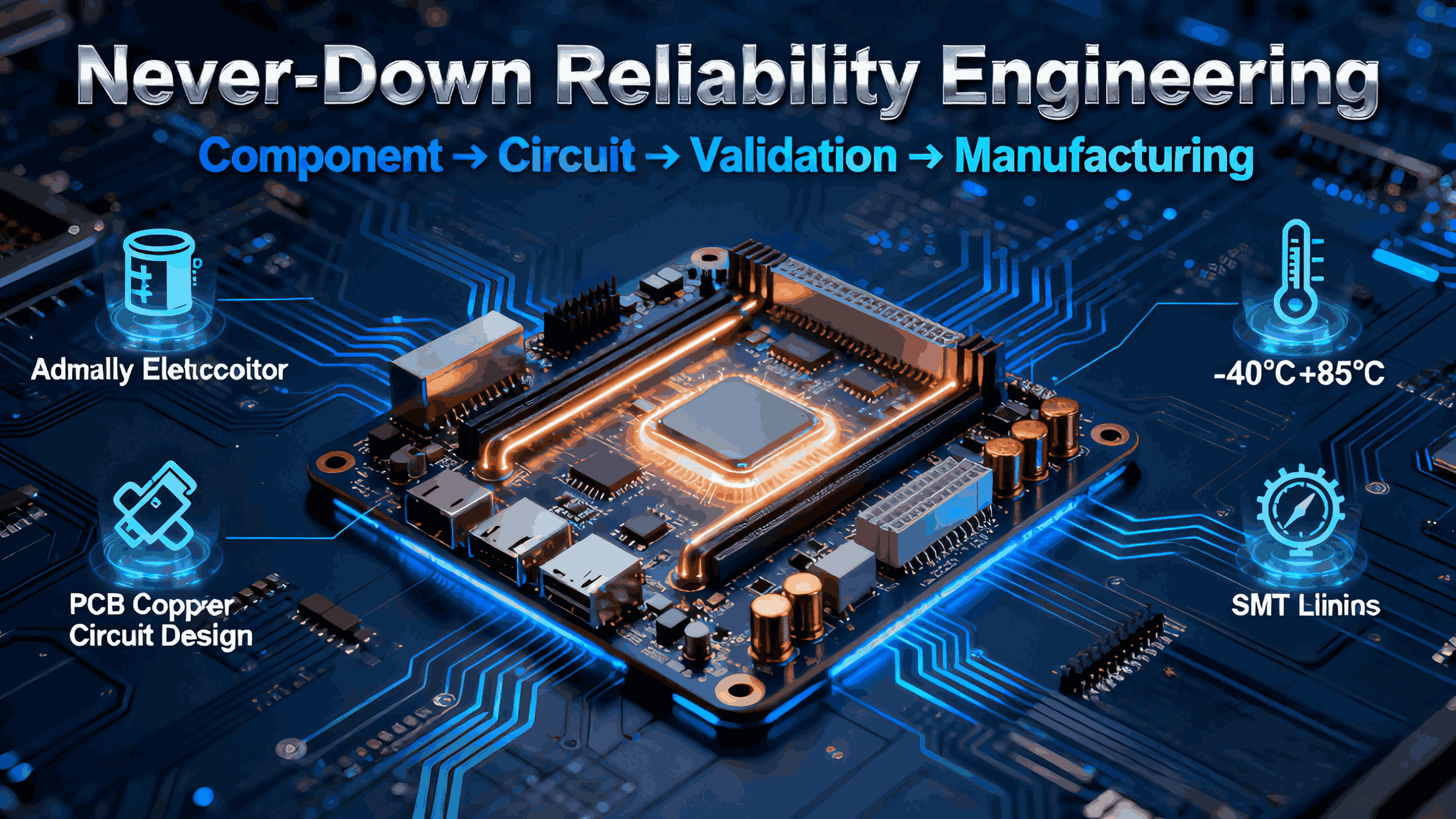

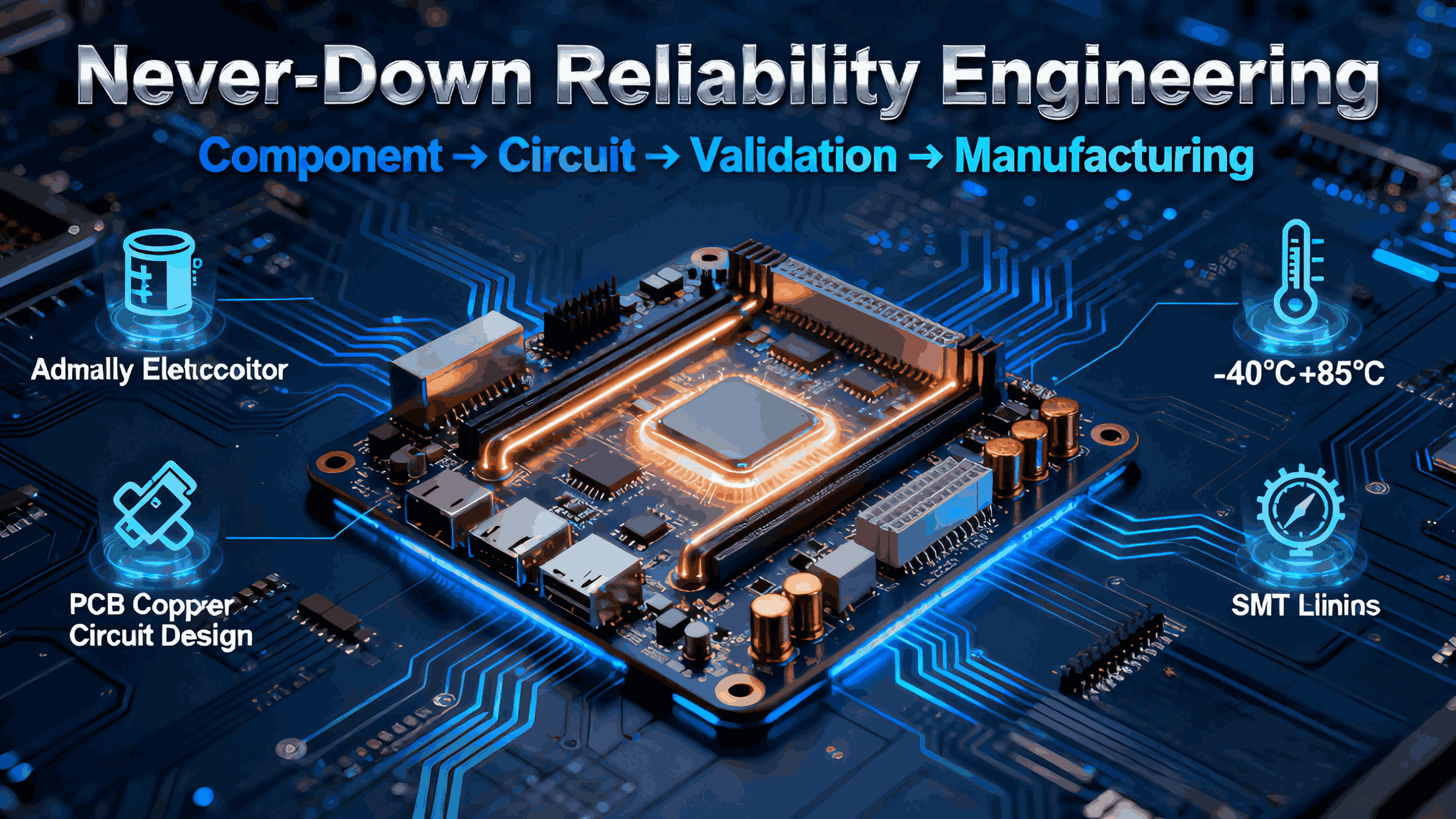

At Shenzhen Angxun Technology Co., Ltd., we treat reliability as a design discipline, not an afterthought. Instead of chasing only higher speed, more cores, or more interfaces, we engineer each product with the internal “DNA” of Never-Down Reliability.

This article breaks down the full engineering chain—from component selection to circuit design to extreme verification—that ensures every motherboard shipped is built to remain stable for years under continuous load.

1. Reliability Starts With Component-Level Engineering

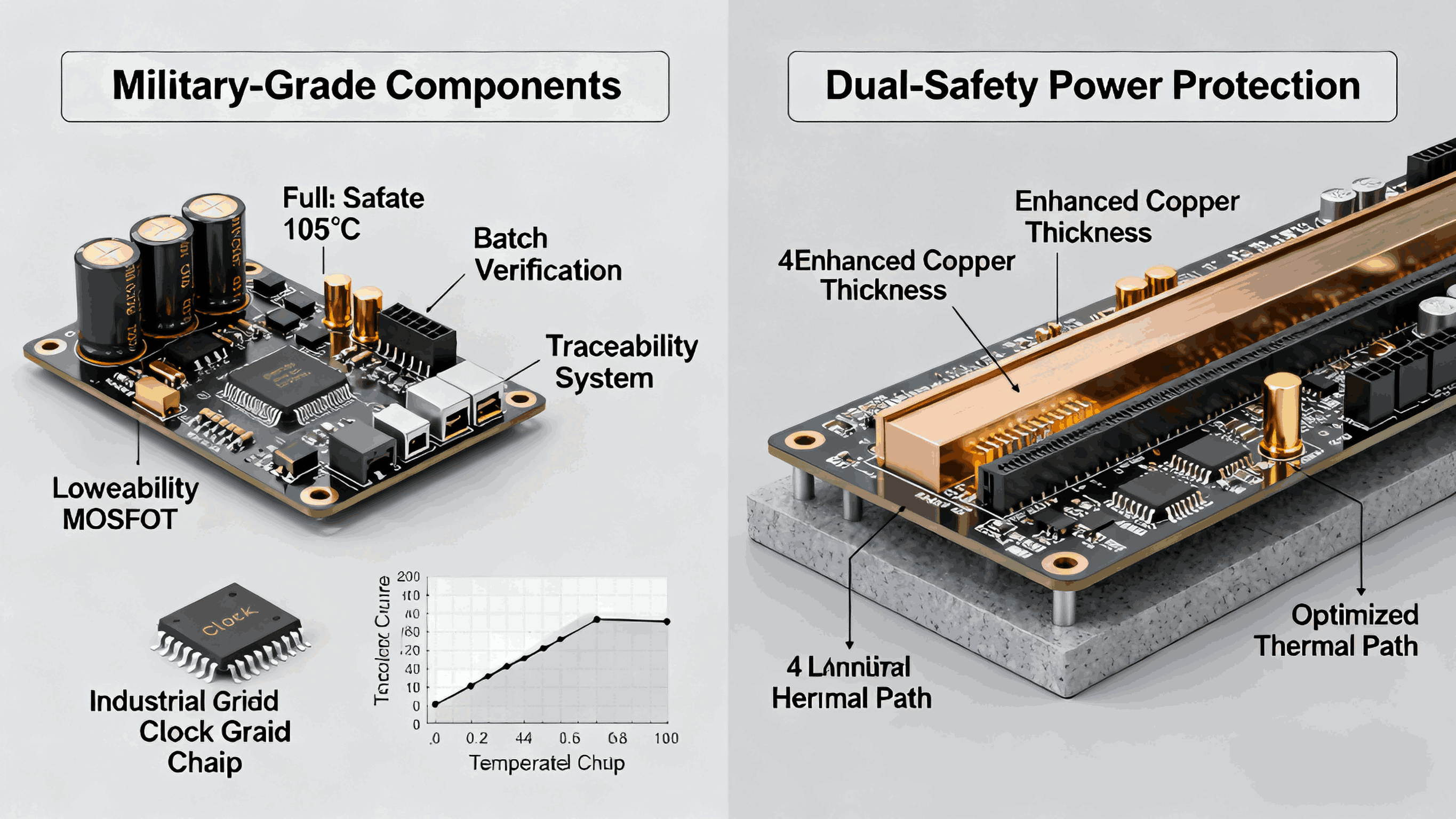

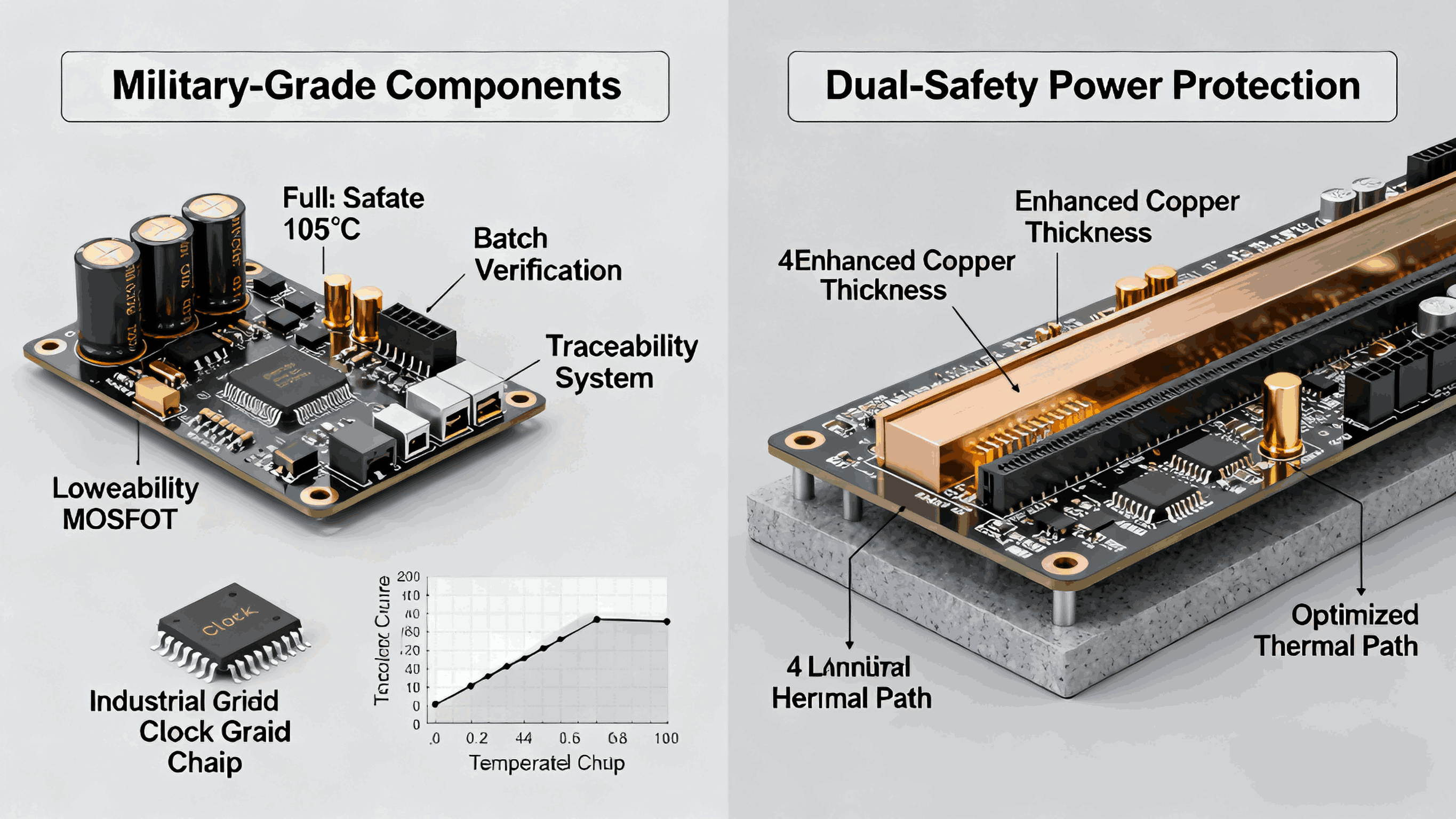

1.1 Military-Grade & Industrial-Grade Components

Where consumer motherboards often use cost-driven components, our engineering team selects:

All-solid capacitors rated for long life and high temperature

High-cycle VRM MOSFETs with low RDS(on)

Industrial-grade clock chips for signal integrity under temperature drift

Long-life polymer capacitors and PCB materials rated for humidity & heat

Every component goes through batch verification, derating analysis, and compatibility mapping.

1.2 Procurement Traceability

Each capacitor, inductor, power IC, and oscillator is tied to:

If a field issue ever occurs, we can trace within minutes which batch of components is affected.

2. Reliability in PCB & Circuit Design

2.1 Power Delivery Architecture Built for Stability

Our motherboards use:

Independent CPU power rails to isolate noise

Dual-safety overcurrent & overvoltage protection

Zero-burning protection circuits to protect CPU & memory under abnormal load

Optimized power plane copper thickness for heat dissipation

This ensures clean, stable power, even under turbo bursts, high I/O load, or degraded environmental conditions.

2.2 PCB Copper Plating for Heat & Signal Integrity

We use enhanced PCB copper plating to improve:

Current carrying capacity

PCB heat spreading

Signal integrity for PCIe, DDR, and USB high-speed lanes

This directly reduces hot spots, voltage ripple, and signal jitter—three common causes of long-term failure.

2.3 Thermal Architecture With “Passive Reliability”

Angxun motherboards incorporate:

Aluminum thermal base for heat absorption

Optimized VRM heat path

Memory & NVMe heat dissipation channels

Intelligent fan curves when paired with OEM cooling solutions

This allows the system to remain stable even during 24/7 sustained workloads or edge deployments at elevated temperature.

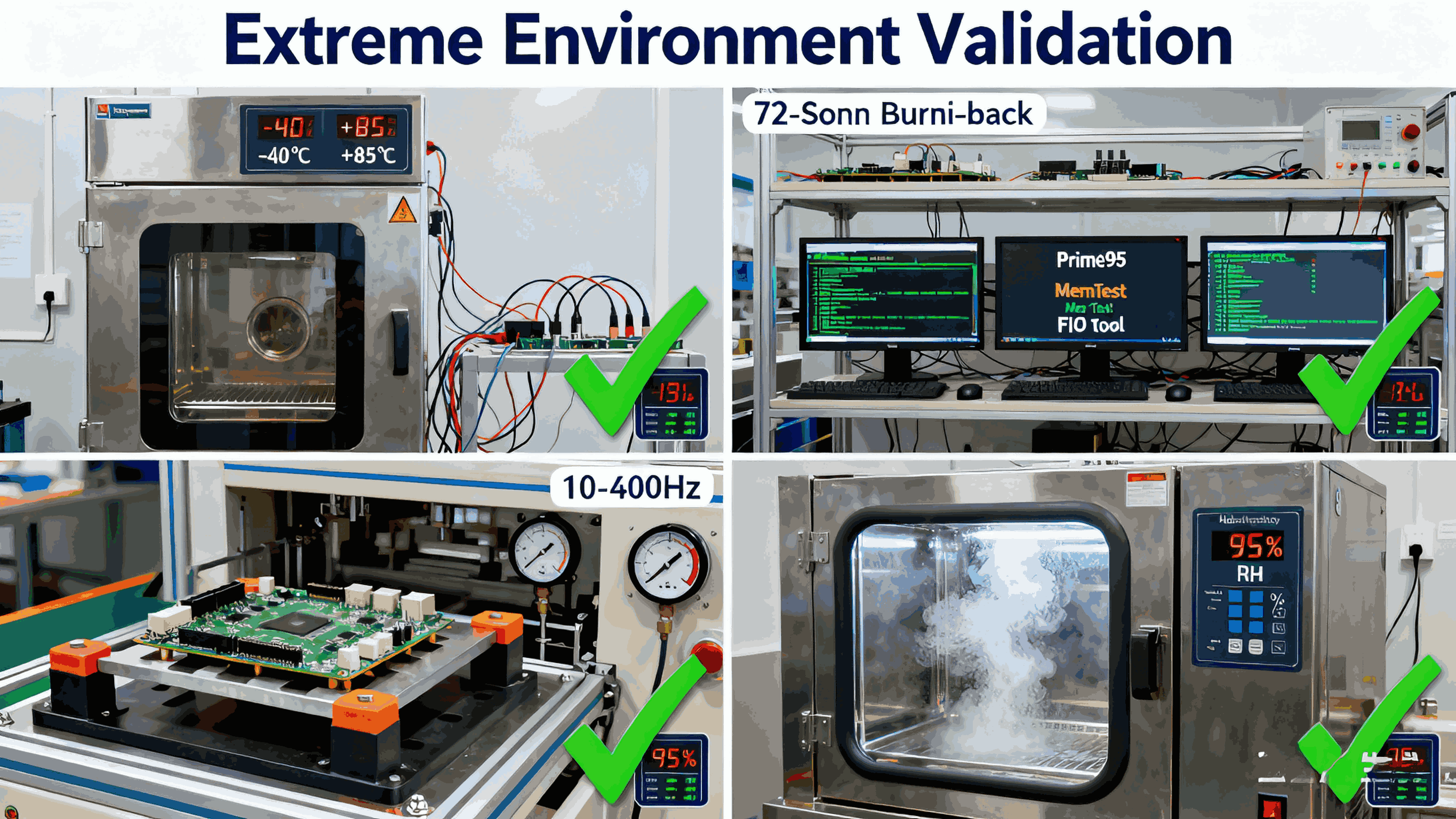

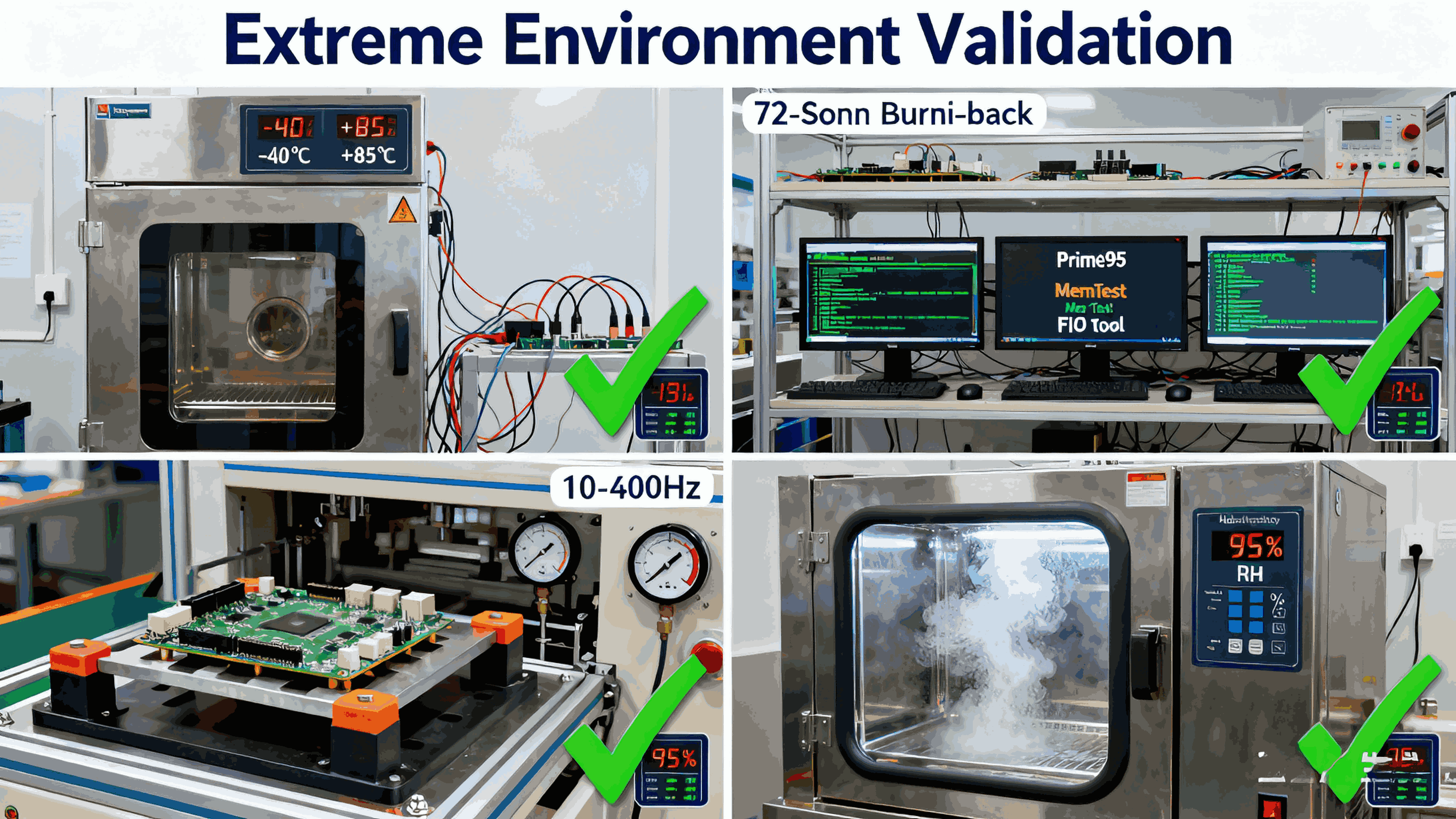

3. Verification: Where Designs Prove Their Reliability

“Never-Down” is not a claim—it must be validated through real engineering tests.

3.1 Wide-Temperature Validation (-40°C to +85°C)

Motherboards undergo:

Cold boot tests at -40°C

Thermal soak and hot boot at +85°C

Power cycling across temperature extremes

Component-level monitoring for drift

This exposes weak solder joints, marginal components, and aging risks.

3.2 High-Concurrency Stress (48–72 Hour Burn-In)

We apply real engineering tools:

This ensures the system remains stable under continuous multi-dimensional workload pressure.

3.3 Vibration, Humidity & Corrosion Resistance

Industrial deployments demand environmental durability:

10–500Hz sine/random vibration tests

95% relative humidity tests

Salt mist corrosion simulation

Long-term dust accumulation stress tests

These simulate real field conditions—from factory floors to outdoor kiosks to vehicle-mounted systems.

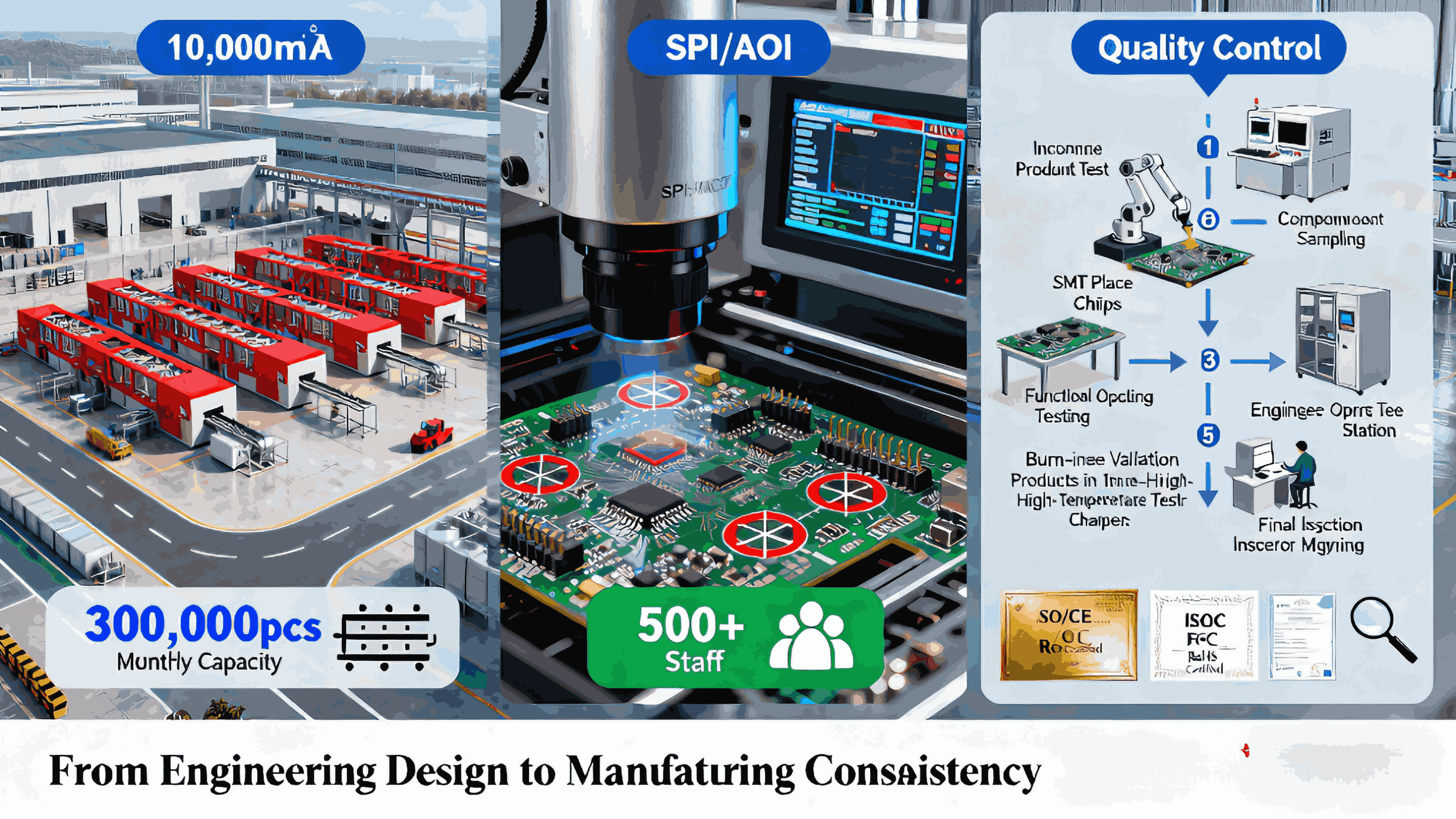

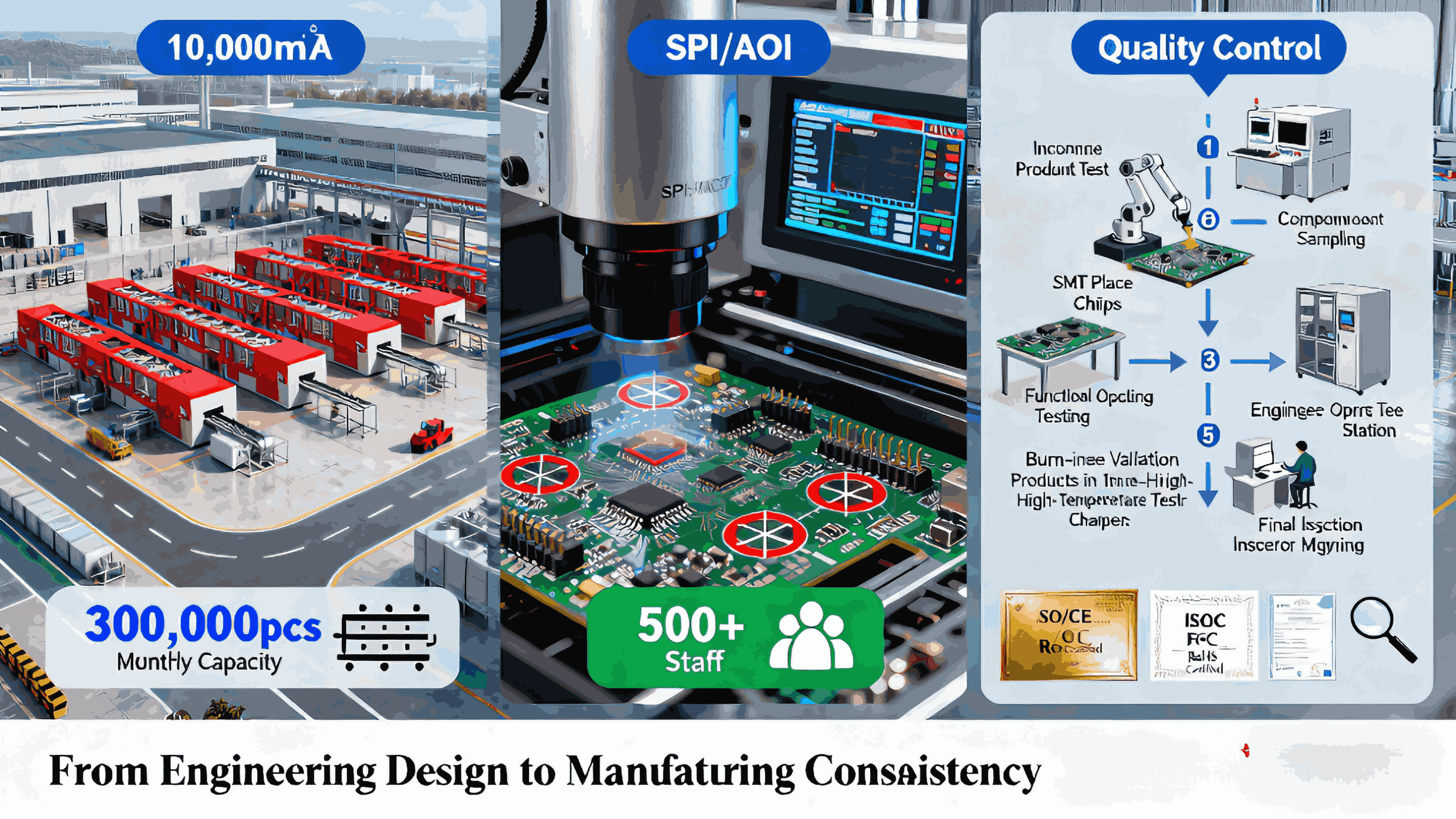

4. Manufacturing: Where Engineering Is Converted Into Consistency

At Shenzhen Angxun Technology, product reliability is supported by world-class manufacturing strength:

10,000㎡ factory with 500+ staff

Five advanced SMT lines with high-precision SPI & AOI

Monthly capacity of 300,000pcs across industrial & consumer motherboards

ISO, CE, FCC, RoHS certified production

Every board is 100% tested for functional, electrical, and firmware stability before shipment.

5. Why “Never-Down Reliability” Is Built Into Every Angxun Motherboard

Because our engineering philosophy is fundamentally different:

Not “pass the test,” but “design for zero failure.”

We embed reliability into:

Component choice

Circuit and power architecture

Thermal engineering

Firmware and BIOS stability

Mass-production quality control

This ensures our motherboards—whether Intel, AMD, industrial, embedded, Mini PC, or server-grade—are built to endure years of uninterrupted operation, even under harsh use cases.

Conclusion: Reliability Is Not a Spec—It Is a Mindset

The difference between a consumer motherboard and a truly reliable industrial/server motherboard is not visible on a spec sheet. It is hidden in:

Component selection

PCB layout

Power integrity

Derating strategy

Stress testing

Traceability

Supply-chain discipline

At Angxun, these principles form the DNA of every product we design and manufacture.

If you need a motherboard platform designed for long life, zero downtime, and mission-critical stability, our engineering team is ready to support OEM/ODM customization.