Let me tell you a story that keeps hardware CEOs awake at 3 AM.

We once worked with a premium home automation brand that thought their 0.1% failure rate was "industry standard." Then they did the math:

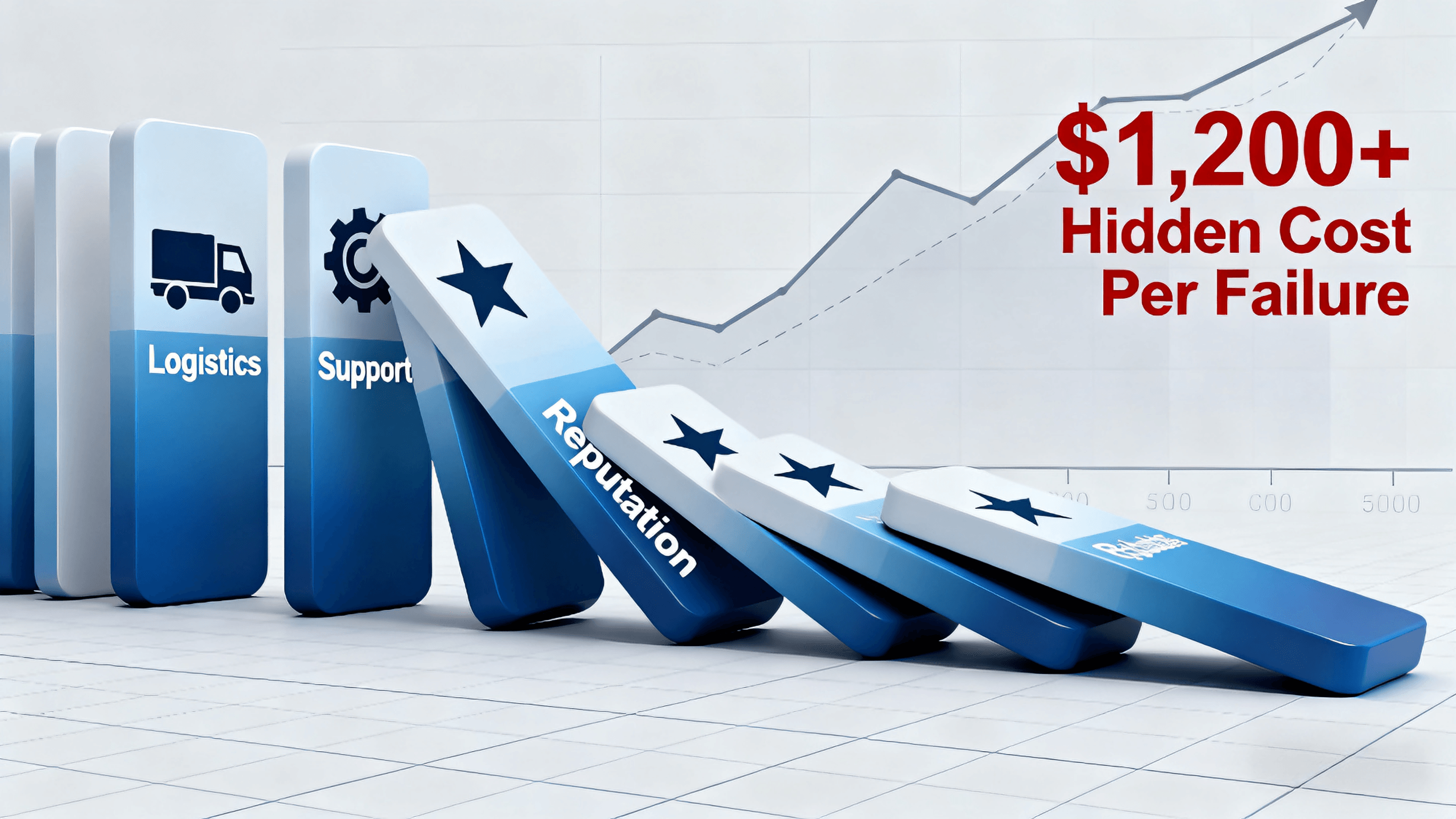

The Domino Effect of a Single Failed Motherboard

• Unit 1,247 fails in a luxury smart home installation

• Technician dispatch: $350 service call + 4 hours travel/repair time

• Customer frustration: Family without climate control/security for 48 hours

• Brand damage: They tell 12 friends about their "unreliable" system

• Online impact: 1-star review that never goes away

Suddenly, that "acceptable" 0.1% failure rate meant they were dealing with 37 preventable crises every quarter across their installed base.

Why the Math Never Works in Your Favor

Most hardware companies calculate failure rates like this:

(Defective Units ÷ Total Shipped) × 100 = Failure Rate

But the real calculation looks more like:

(Defective Units × (Logistics + Support + Reputation + Lost Future Revenue)) ÷ Total Shipped = True Cost

The Multiplier Effect in Action

Let's break down what really happens when that 0.1% failure rate materializes:

Logistics Nightmare

Reverse logistics costs: 2-3× original shipping cost

Warehouse processing and inventory adjustment

Replacement unit allocation and shipping

Actual cost: ~$420 per return

Support Team Meltdown

45 minutes per case in support ticket handling

Engineering time for failure analysis

Customer service escalations

Actual cost: ~$230 in internal resources

Brand Reputation Erosion

37% of customers won't rebuy after a negative experience

Negative reviews impact conversion rates by up to 15%

Social media amplification of complaints

Actual cost: Incalculable, but massive

The "We Fixed It" Fallacy

Many companies think their 0.1% failure rate is fine because "we have great warranty support." But customers don't buy your products for the excellent RMA experience.

As one of our clients (a router manufacturer) discovered:

Before: 0.08% failure rate, "industry leading"

After investigation: Each failure cost them $1,200+ in hidden costs

Realization: They were spending more on processing failures than it would cost to prevent them

The Engineering Reality Check

When we dig into why companies accept these "low" failure rates, we typically find:

Test Coverage Gaps

Environmental testing that doesn't match real-world conditions

Inadequate burn-in periods that miss infant mortality failures

Component-level testing that misses system-level interactions

Supply Chain Blind Spots

Second-source components with subtle performance differences

Manufacturing process variations across different facilities

Counterfeit components that pass initial testing but fail early

The Prevention Math That Actually Works

We helped an industrial PC manufacturer completely rethink their approach:

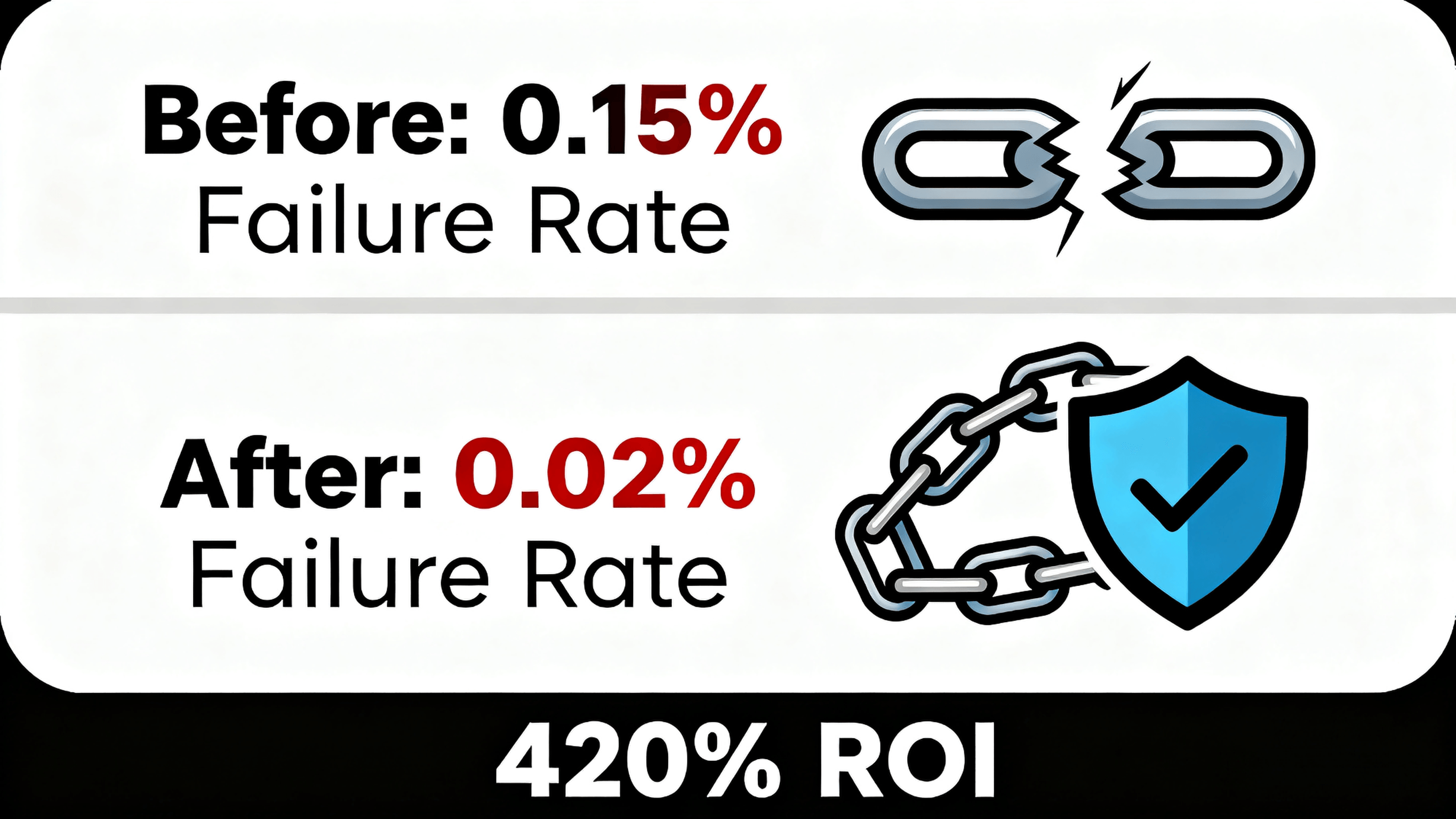

Before Optimization

0.15% field failure rate

$280,000 annual warranty costs

3.2/5 customer satisfaction for reliability

After Implementing True Prevention

0.02% field failure rate (7.5× improvement)

$38,000 annual warranty costs

4.7/5 customer satisfaction

ROI: 420% in first year alone

How They Did It:

Extended Environmental Testing

144-hour continuous burn-in vs industry standard 24-hour

Thermal cycling from -40°C to 85°C (not just 0°C to 70°C)

Vibration testing simulating shipping and installation environments

Component-Level Lifecycle Analysis

Predictive failure modeling for every component

Supplier performance tracking with consequences

Proactive replacement of components nearing end-of-life

Real-World Simulation

Testing in actual customer environments before full production

Monitoring early deployment units with enhanced telemetry

Continuous feedback loop from field failures to design improvements

The Hard Truth

If you're shipping hardware at scale, there's no such thing as an "acceptable" failure rate. Every defective unit that reaches a customer is a small business crisis waiting to happen.

The companies that understand this don't see quality as a cost center—they see it as their most powerful marketing tool.

Your Move

What's your "acceptable" failure rate really costing you? Have you calculated the true multiplier effect across your organization?

Industry veterans: What failure rate do you consider truly acceptable for different product categories?

Hardware startups: Are you building your quality processes around preventing failures or processing returns?

Quality engineers: What testing methodologies have you found most effective for catching that last 0.1% of potential failures?

Based on 11 years of hardware manufacturing data across consumer electronics, industrial systems, and enterprise hardware. All cost calculations verified through client implementation data and industry benchmarking studies.

Contact: Tom

Phone: 86 18933248858

E-mail: tom@angxunmb.com

Whatsapp:86 18933248858

Add: Floor 301 401 501, Building 3, Huaguan Industrial Park,No.63, Zhangqi Road, Guixiang Community, Guanlan Street,Longhua District,Shenzhen,Guangdong,China

We chat