For OEMs and solution providers serving global markets in industrial automation, smart infrastructure, and mission-critical applications, a fundamental question dictates long-term viability: Is our hardware lifecycle aligned with our solution lifecycle? Discrepancy between the two represents one of the most significant, yet overlooked, business risks.

The Core Problem: Asymmetric Lifecycles

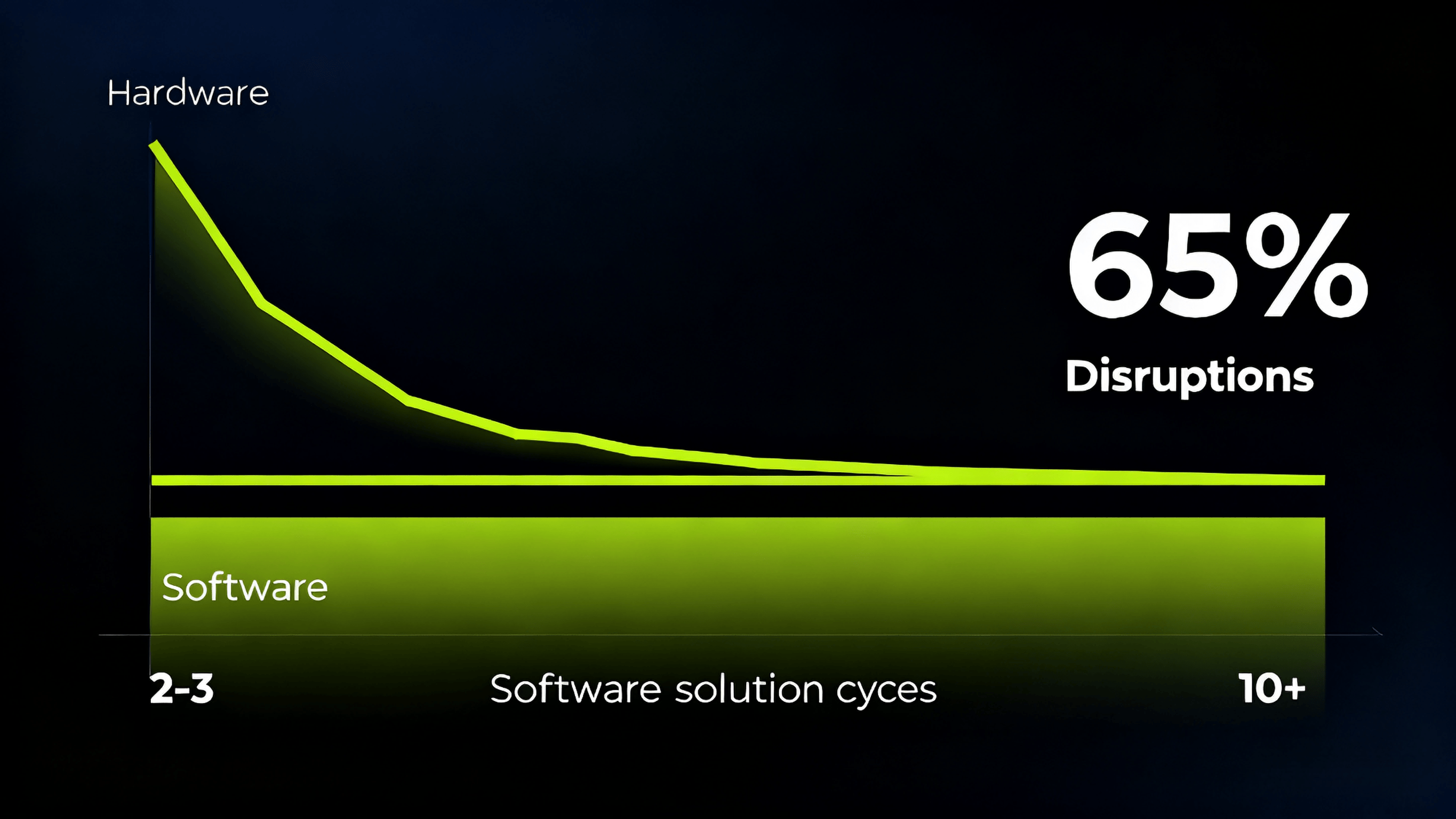

The technology hardware industry operates on 2-3 year product refresh cycles. However, the solutions you build—whether industrial control systems, medical devices, or public infrastructure—often require 10+ years of operational life. This creates an inevitable asymmetry.

Quantifying the Risk:

A 2023 analysis by Gartner highlighted that 65% of organizations experienced operational disruptions due to premature hardware obsolescence. The financial impact included:

Unplanned R&D costs for system redesign: $250K - $1.5M per product

Emergency component sourcing premiums: +300-500% cost increases

Contract penalties and reputational damage: Inc calculable

The Lifecycle Alignment Framework: A Strategic Imperative

True hardware partnership requires synchronization across three critical dimensions:

1. Temporal Alignment: Guaranteed Longevity

10-Year Minimum Product Availability: Contractually guaranteed for core platform components.

Advanced Change Notifications (PCN): 24-month minimum advance notice of any changes.

Guaranteed Spare Inventory: Secured component inventory for the full service life.

2. Technological Alignment: Future-Proofed Design

Backward-Compatible Architecture: Ensuring new generations interface with legacy deployments.

Performance Headroom: Designing in 30-40% performance margin for future software updates.

Standardized Interfaces: Maintaining consistency across generations (e.g., PCIe, USB, SATA specifications).

3. Service Alignment: Persistent Support

Security Patch Commitment: Guaranteed CVE monitoring and patches for the full lifecycle.

Expert Availability: Access to engineers familiar with your specific implementation.

Knowledge Preservation: Comprehensive documentation and issue tracking maintained for the product lifespan.

Case Study: Global Smart City Infrastructure Provider

Challenge: Ensure 99.99% uptime for public safety network across 5,000 nodes over 8+ years.

Solution: Implemented our Lifecycle Alignment Framework with contractually guaranteed support.

Results:

Zero unplanned hardware-related outages over 8 years

60% reduction in total maintenance costs versus previous vendor

Successful through 2 planned hardware refresh cycles with zero service interruption

Actionable Next Steps:

Conduct a Hardware Lifecycle Audit

Map all critical components against supplier lifecycle commitments

Identify single points of failure and obsolescence risks

Quantify potential financial exposure

Evaluate Partners Against These Criteria:

Do they provide contractual lifecycle guarantees?

What is their historical track record for long-term support?

How do they handle technology transitions?

Frequently Asked Questions (FAQ)

Q: How can you guarantee 10-year availability when chipset suppliers discontinue products?

A: Through multi-generational design strategies, secure component inventory management, and transparent transition planning when changes are unavoidable.

Q: What specific industries most require lifecycle alignment?

A: Medical devices, industrial automation, telecommunications, transportation, energy, and public infrastructure—any sector where solutions must operate for decades.

Q: How is this different from standard extended warranty programs?

A: This is a strategic partnership model encompassing product planning, design collaboration, and continuous support—far beyond simple repair services.

Contact: Tom

Phone: 86 18933248858

E-mail: tom@angxunmb.com

Whatsapp:86 18933248858

Add: Floor 301 401 501, Building 3, Huaguan Industrial Park,No.63, Zhangqi Road, Guixiang Community, Guanlan Street,Longhua District,Shenzhen,Guangdong,China

We chat